Complete Production Line Introduction

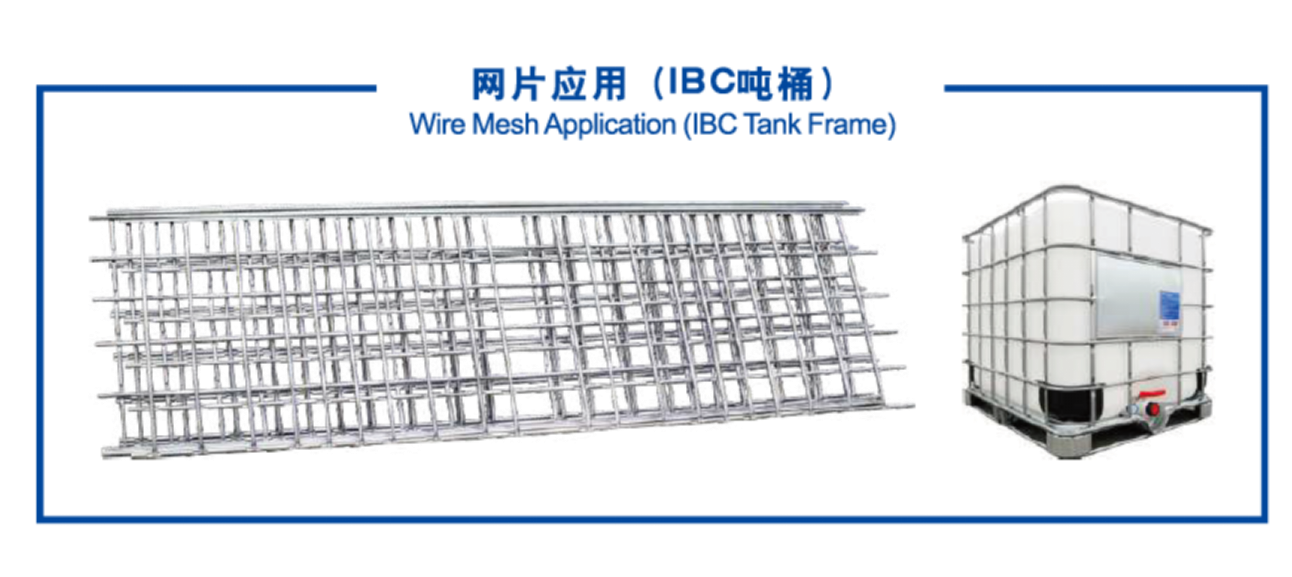

2024-01-11 19:51As an industry leader in manufacturing equipment, we are proud to introduce our comprehensive solution for IBC cage frame production. Our cutting-edge machines, including the IBC cage frame welding machine, bending machine, locking machine, and punching machine, offer exceptional precision and efficiency, ensuring the highest quality IBC cage frames.

The production process begins with the IBC cage frame welding machine, which forms the foundation of our manufacturing line. With its advanced control system and precise temperature and pressure control, welding machine guarantees stable and reliable welds, ensuring the structural integrity of the cage frames. The machine's fast welding speed and automated operation significantly reduce production time and increase efficiency.

Complementing the welding machine is our bending machine, which ensures precise and accurate shaping of the cage frame components. With its adjustable bending angles and high-speed operation, bending machine guarantees the perfect fit and form for each frame. The bending machine is designed for versatility, accommodating various frame sizes and configurations.

To secure the components together, our locking machine provides a reliable and robust solution. With its powerful locking force and adjustable settings, locking machine ensures a tight and secure connection, enhancing the overall strength and stability of the IBC cage frames. The locking machine's user-friendly interface and automated operation make locking machine easy to use and highly efficient.

Completing our production line is the punching machine, which adds necessary openings and features to the cage frames. With its precise punching capabilities and customizable tooling options, punching machine allows for the creation of various openings, such as access doors, handles, and inspection windows. The punching machine ensures accuracy and consistency in every punch, meeting the specific requirements of each frame design.

Our production process continues with unloading the completed cage frames and proceeding to the base frame welding. The base frame is securely welded to provide additional stability and support to the cage frame structure. The base frame loading follows, ensuring proper alignment and positioning.

Next, the inner tank loading takes place, where the tank is carefully placed into the cage frame. Automatic valve welding ensures a leak-free connection between the tank and the frame, ensuring the integrity of the IBC system. A thorough leakage detection process is performed to ensure the highest quality standards are met.

The automatic cover tightening process ensures a secure and tight seal, protecting the contents of the IBC. The tank is then placed into the frame, and the manual assembly of the pull rod completes the assembly process. Finally, the finished products are stacked and prepared for distribution.

At our industry-leading company, we are committed to providing not only the highest quality machines but also exceptional service and support. Our team of experts is available to assist with installation, training, and ongoing technical support, ensuring a seamless integration of our machines into your production process. We understand the importance of minimizing downtime and maximizing productivity, and we are dedicated to helping you achieve your manufacturing goals.

In conclusion, our comprehensive solution for IBC cage frame manufacturing sets a new standard in the industry. With our advanced machines, including the IBC cage frame welding machine, bending machine, locking machine, and punching machine, we offer exceptional precision and efficiency. Trust our industry-leading company for all your IBC cage frame production needs, and experience the difference in quality and performance.

| Production Line Configuration | |

| Production Capacity | 90 sec/pc |

| Total plant electricity requirement | 550KW |

| Air Switch | more than 600A |

| Water Requirement | 10-25m3/hour |

| Air Requirement | 1.1m3/min |

| Production Rate | 320pcs/8 hours |