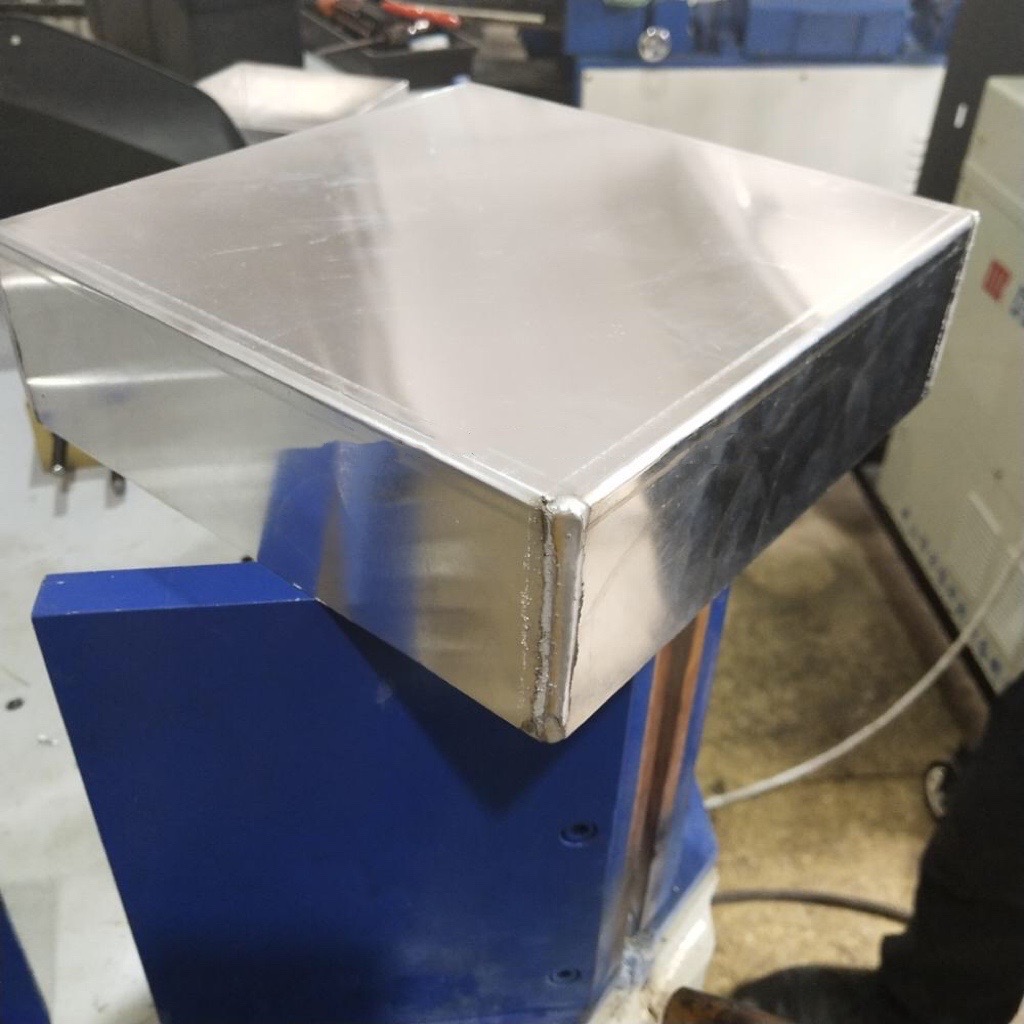

Automatic CO₂ Seam Welder Metal Boxcase Corner Seam Welder

Feature:

1) Most Durable Spot Welding Machine

2) Specially suitable for welding higher conductive rate of material(such as aluminum, copper, silver and so on)

3) High quality, high efficiency,98% power factor, three-phase input load balancing, the impact on the user grid greatly reduced,DC input current, smooth, inductance is zero,1000HZ working frequency, time control precision is 1MS

4) Fastest Welding Machine. Capacity is important to factory. To use less labour, and more productive, our welding machines can reach your goal.

- JIANJIN

- Guangdong,China

- 7 days

- 20 sets per month

- Information

The Automatic CO₂ Seam Welder is a top-of-the-line welding solution for manufacturing industries that require efficient, high-quality welds. With its advanced technology and innovative features, this machine offers superior welding capabilities, ensuring precise, consistent, and strong welds.

CO₂ Seam Welder:

The CO₂ Seam Welder is a key component of the Automatic CO₂ Seam Welder, utilizing CO₂ as the welding gas. CO₂ offers a faster welding process and produces a clean, strong weld bead with minimal spatter. This results in faster production times and improved weld quality, making the CO₂ spot welding machine an excellent choice for a range of manufacturing applications.

Full Automatic Welding Machine:

The Full Automatic Welding Machine offers seamless integration with various materials and components, ensuring consistent, repeatable welds. The CO₂ spot welding machine features advanced control systems that allow for precise weld tracking and seam following, eliminating the need for manual manipulation during the welding process. This automation not only improves weld quality but also increases production efficiency, reducing labor costs and improving overall productivity.

Semi Automatic Welding Machine:

The Semi Automatic Welding Machine offers a balance between manual and automatic operation, providing operators with more control over the welding process. the CO₂ spot welding machine ideal for those who require more flexibility in their welding operations, allowing for customization and adaptability to different welding applications. The Semi Automatic Welding Machine provides operators with the ability to manually guide the torch along the seam, while the machine handles the weld tracking and seam following, ensuring consistent and reliable welds.

Versatile Applications:

The Automatic CO₂ Seam Welder is designed for a wide range of applications, making the CO₂ spot welding machine a valuable addition to any manufacturing operation. Whether you're producing metal boxes, cases, or other components requiring corner seam welds, this machine has the capabilities to handle your needs. the CO₂ spot welding machine perfect for industries such as packaging, furniture, hardware, and more.

In conclusion, the Automatic CO₂ Seam Welder is a top-of-the-line solution for manufacturers seeking to improve productivity, precision, and quality in their welding operations. With its CO₂ Seam Welder, Full Automatic Welding Machine, Semi Automatic Welding Machine, and versatile applications, this machine is designed to meet the demands of a range of industries. Contact us today to learn more about how our Automatic CO₂ Seam Welder can help take your welding operations to the next level.

Automatic CO₂ Seam Welder Metal Boxcase Corner Seam Welder

Main Parameter

Automatic CO₂ Seam Welder Metal Boxcase Corner Seam Welder

Model: ZHR-300

Input Voltage: Single Phase 220V, 50/60Hz

Max. Welding Height: 300MM

Min.Welding thinckness: above 1.2mm

Welding Speed: 300-2000mm/min

Product Detail