CNC Spot Welder Handheld Fiber Laser Welding Machine

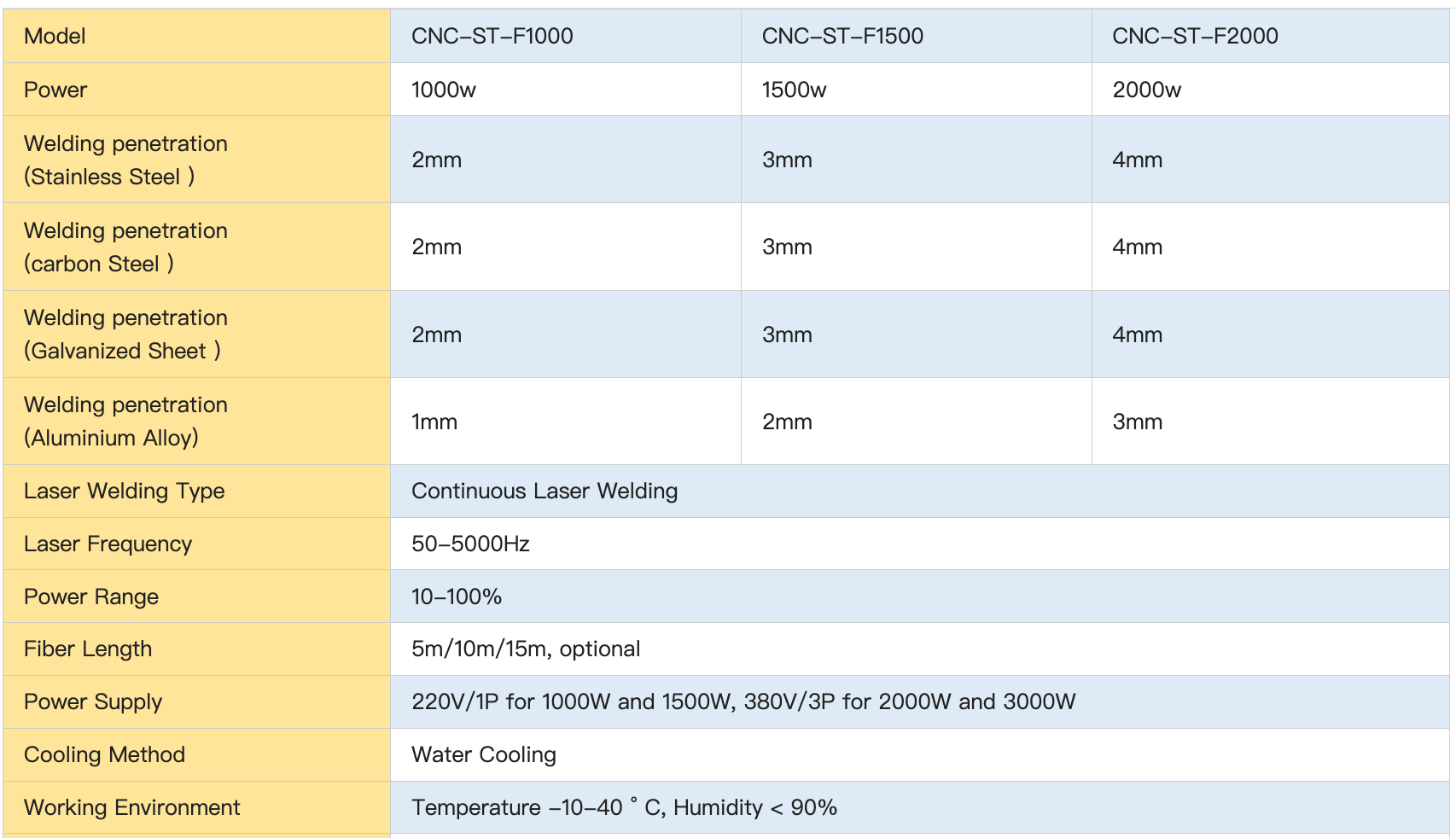

1. Handheld welding head is equipped with 1000 watt fiber laser power, flexible, enabling outdoor welding.

2. Fast welding speed, 2-10 times faster than traditional welding.

3. The welding seam smooth and beautiful, large depth, small taper, don't need polish, save time.

4. No deformation or welding scar, firm welding of the workpiece.

5. Laser welding has less consumables, low energy consumption and long service life.

6. Safety, easy operation and more environmentally friendly.

- SCN CNC

- Guangdong,China

- 1days

- 150sets/month

- Information

In many fields such as biomedicine, electronics, automotive, powder metallurgy, manufacturing, and metal processing, welding technology has always been an indispensable key link. With the advancement of technology, handheld laser welding machines are gradually becoming a new favorite in these fields due to their efficient and precise characteristics.

A handheld laser welding machine uses high-energy laser pulses to locally heat materials in a small area. The energy radiated by the laser quickly diffuses into the material through thermal conduction, causing the material to melt and form solid solder joints in a short period of time. This welding method not only has a fast speed, but also the weld seam is flat and beautiful, without the need for complex processing after welding, greatly improving production efficiency.

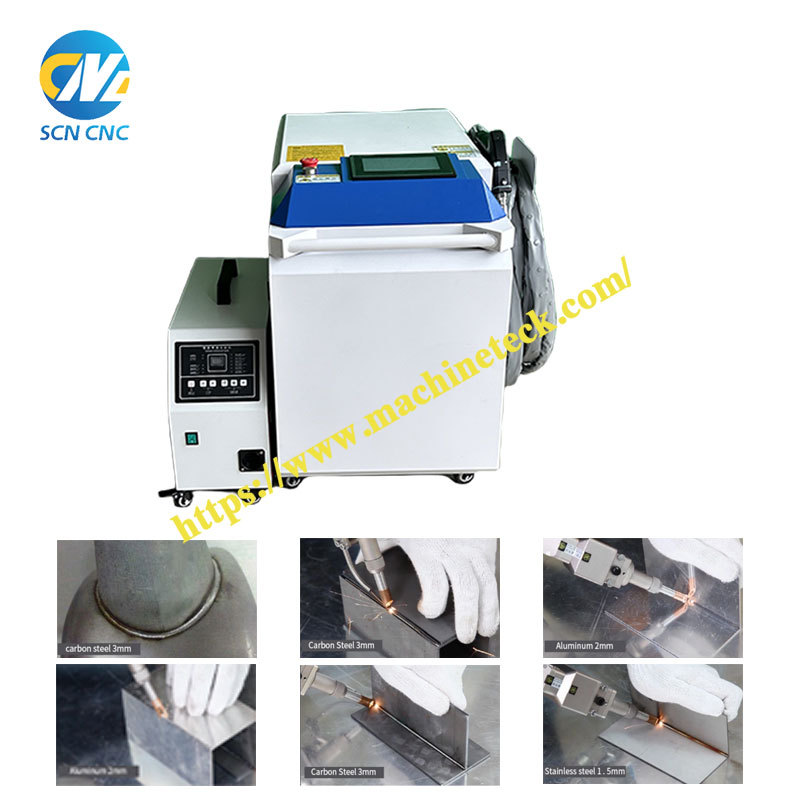

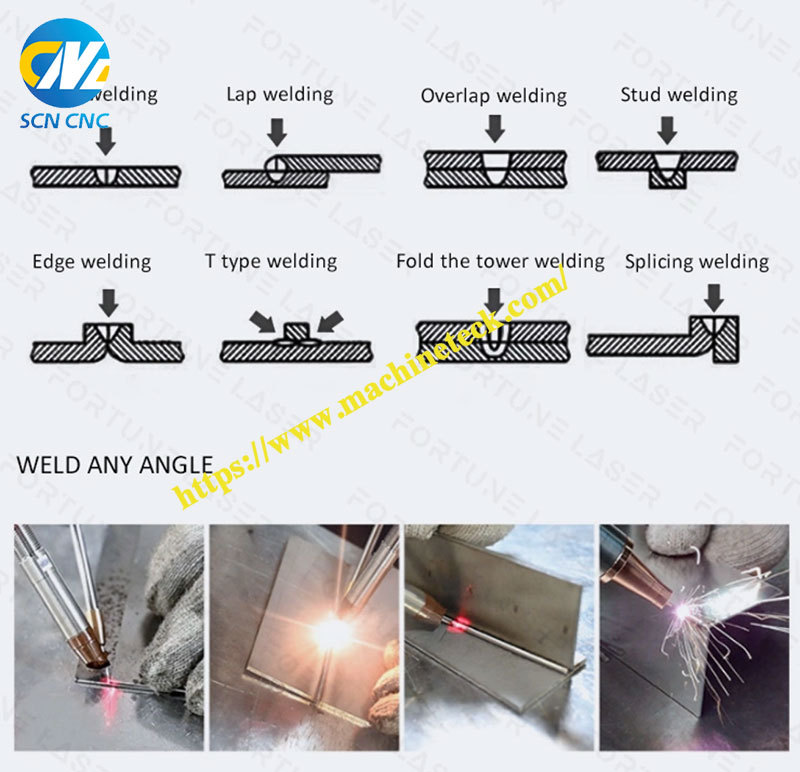

The fiber laser welder is worth mentioning that handheld laser welding machines are mainly designed for welding thin-walled materials and precision parts. Whether the fiber laser welder is spot welding, butt welding, overlap welding, or seal welding, the fiber laser welder can easily handle. The width of the weld seam is small, the heat affected zone is small, and the deformation is small, which greatly improves the welding quality.

In addition, the focus photoelectric of the handheld laser welding machine is small, the positioning accuracy is high, and the welding process can be precisely controlled, avoiding the errors that may occur in traditional welding methods. At the same time, its easy to automate feature also makes the welding process more convenient and efficient.

In the field of biomedicine, handheld laser welding machines can be used for precision welding of medical devices, ensuring product safety and reliability; In the electronics industry, handheld laser welding machines can be used for welding small parts to improve product performance and stability; In the automotive industry, handheld laser welding machines can be used for welding body, chassis and other components, improving the safety and durability of vehicles.

In summary, handheld laser welding machines are leading a new revolution in welding technology with their high efficiency, precision, and ease of automation. Regardless of the industry, as long as welding technology is needed, handheld laser welding machines will be a rare and helpful tool for you.

Basic Info

| Model No | CNC-ST | Laser Classification | Optical Fiber Laser |

| Type | Protable Welding Machine | Pulse Width | 0.05-4mm |

| Laser Source Brand | Raycus, Max, Jpt, Reci, etc | Focal Spot Diameter | 0.2-3.0mm |

| Wavelength | 1064-1080nm | Laser Power | 1000/2000/3000W |

| Welding Mode | Manual Handheld | Welding Depth | 0.1-3.0mm |

| Application Material | Aluminum Stainless Steel Carbon Steel | Power Supply | 220V/380V 50Hz/60Hz |

| Core Components | Laser Source | Specification | 530x885x665mm |

| Warranty of Core Components | 2 Years | Power Density | Deep Fusion Welding |

| Origin | Guangdong,China | Aiming and Positioning | CCD and Red Right |

Technical Parameters