- Home

- >

- News

- >

- Company news

- >

News

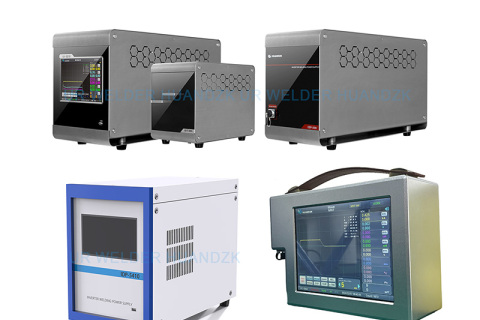

IDP series inverter DC welding power supply has the advantages of high-precision control, strong welding stability, multi-stage adjustable pressure, intelligent management and multi-frequency switching, which can adapt to complex welding needs.

During the Spring Festival holiday from January 20 to February 5, 2025, we suspended production but the business team was on standby. The core products include welding power supplies and intelligent solutions, with innovative functions such as multi-stage welding and servo control.

The HD-400B all-purpose welding detector has real-time data collection, quality judgment, high-definition touch display and powerful database functions, supports a variety of equipment and communication protocols, and comprehensively improves welding quality management and production efficiency.

We will showcase its advanced IDP series precision welding power supplies at the Poland International Welding Technology and Equipment Exhibition. With precise control, intelligent monitoring and innovative technology, it will promote the development of the welding industry and provide efficient and stable intelligent welding solutions.

China's leading welding power supply manufacturer participated in the Kielce International Welding Fair in Poland, focusing on ultra-precision, inverter, high-frequency DC welding power supplies and intelligent welding solutions, demonstrating its technological innovation capabilities.

IDP-620 welding power system is specially customized for welding of automotive parts. It features high-precision digital control, intelligent operation, stability and reliability. It is suitable for a variety of welding processes, is highly efficient and energy-saving, and has comprehensive safety protection, facilitating high-quality production.

Huandian HD-400B welding analyzer equipment monitors welding current, voltage, time and other parameters in real time with high precision. Welding testing equipment is convenient for data storage and analysis, improves welding quality and efficiency, and is suitable for automotive, home appliances, aerospace and other fields.

The HD-400B welding monitoring device has the following notable advantages: high-precision real-time monitoring, comprehensive data analysis, wide applicability, excellent standard discrimination, large-screen viewing display, enhanced data traceability, rich communication interfaces and efficient statistical monitoring.

Huandian specializes in the manufacture of high-precision spot welding machines, providing a variety of excellent performance equipment with ultra-high welding accuracy and powerful quality monitoring systems. Through continuous research and development and innovation, Huandian leads the industry in welding control accuracy, functional stability and production efficiency to meet the diverse needs of customers.

Our core products include ultra precision welding power supplies, precision inverter welding power supplies, high power high frequency DC welding power supplies, high frequency transformers and other hardware essentials; at the same time, we also provide intelligent solutions such as multi functional welding monitors, welding networking group control systems and welding quality monitoring systems

We focus on welding technology and intelligent solutions, provide hardware such as ultra precision welding power supplies and intelligent systems such as welding monitoring and networking group control, and will appear at the 20th Vietnam International Machinery Equipment and Industrial Technology Exhibition in 2024.

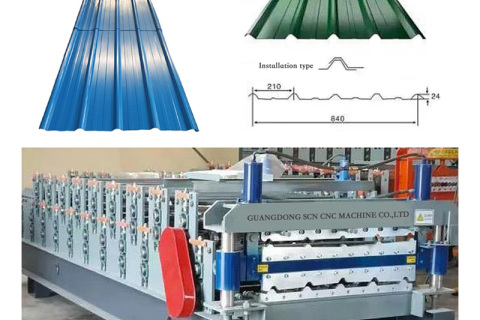

Spanish customers inspected our roll forming machine and appreciated its high efficiency, precision, energy saving and environmental protection advantages. They look forward to deepening cooperation and creating a better future.