- Home

- >

- News

- >

- Product Line Video

- >

News

A magical tool for monitoring resistance welding machines, compatible with multiple types, capable of measuring current, voltage and power, alarming within seconds of exceeding the limit, storing millions of data, and keeping track of welding quality!

The precision resistance welding equipment integrates intelligent monitoring, real-time detection of current, voltage and other parameters, automatic alarm when exceeding the limit and rejection of defective products; built-in large-capacity database stores welding data and fault records, supports USB flash drive export and analysis; multi-stage welding is combined with slow rise and slow fall technology to effectively reduce spatter and improve welding stability.

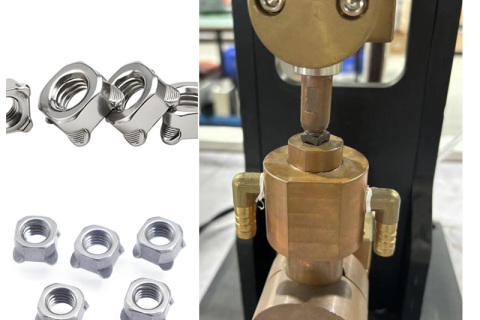

The precision welding spot welding machine adopts 0.2 millisecond high-precision control and servo pressure system, combined with mechanical positioning and electrical signal detection dual anti-reverse technology, to achieve low thermal damage and high stability in nut welding. The strength of the weld is more than 90% of the parent material, and the defective rate is less than 0.5%. It is widely used in high-precision manufacturing fields such as automobiles and electronics.

The projection welding nut error proofing detector improves welding quality and efficiency, prevents errors, and helps efficient production. Welding analyzer equipment is a powerful assistant and high-quality equipment in industrial production.

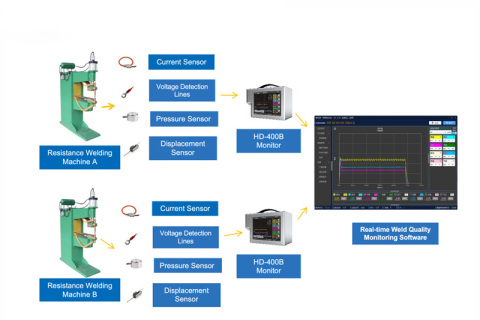

The welding quality monitoring system can collect and display the key parameters such as welding current and voltage of single or multiple resistance welding equipment in real time. Welding quality monitoring system has over-limit alarm and network communication capabilities, can record data and support historical tracing.

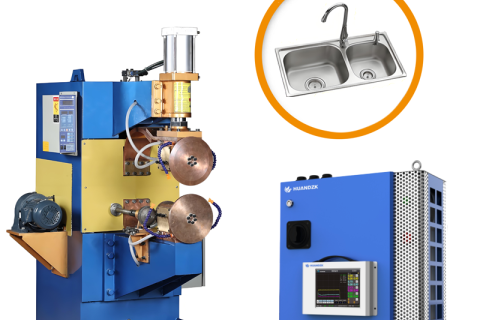

Features of the seam welding machine: high efficiency, stability, reliability, suitable for continuous welding of thin plate materials. Application areas: aerospace, automobile manufacturing, petrochemical and other industrial fields.

The resistance spot welding machine is equipped for resistance seam welding, utilizing resistance welding electrodes.

Copper wire terminal welding relies on a high-efficiency spot welding machine with a built-in special resistance welding transformer. Resistance spot welder uses the principle of resistance welding to achieve precise welding and ensure a firm connection.

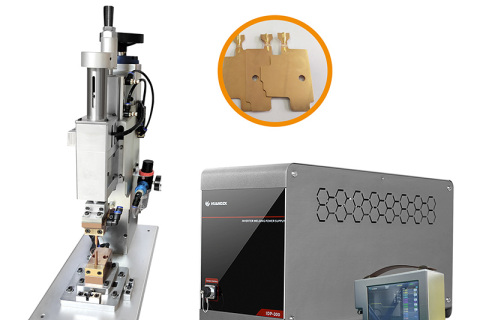

IDP series inverter DC welding power source, as a masterpiece independently developed by Huandian, integrates high-frequency inverter and advanced DSP control technology. The core components are selected from imported components to ensure the excellent performance and long-term durability of the product. Its high-precision control system (accuracy up to 0.2 ms), low-heat design, micro-damage treatment of workpieces, beautiful weld appearance, strong welding tension