- Home

- >

- News

- >

- Industry news

- >

News

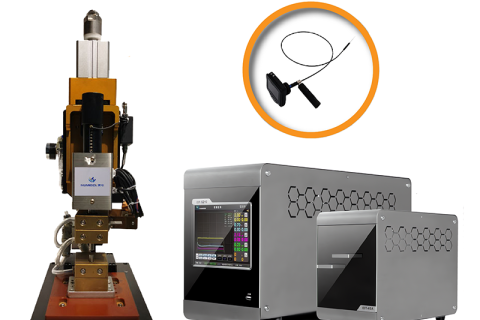

380V copper wire welding machine is known for its high efficiency and reliability, and is widely used in the fields of electronics and electrical appliances. Its high-precision welding technology ensures quality and is suitable for copper wires of multiple specifications. When choosing, you need to consider power, technical parameters and brand quality. Huandian IDP series inverter DC welding power supply uses imported components and advanced technology to provide precise control and low-damage welding, helping enterprises to produce efficiently.

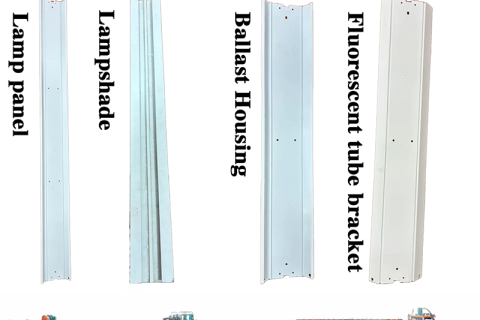

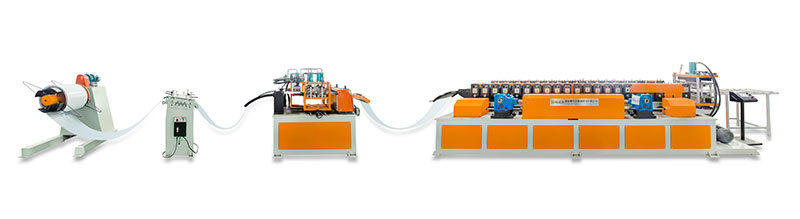

The cold roll forming machine offers distinct advantages and characteristics. Its precision engineering ensures accurate shaping of metal sheets into intricate profiles, enhancing product quality and structural integrity. Versatility is a key feature, allowing customization for various material thicknesses, widths, and specific profile requirements. Automation enhances efficiency, reduces waste, and minimizes downtime, contributing to cost savings and faster turnaround times. Environmental benefits, including lower energy consumption and minimal waste, make it a sustainable manufacturing solution.

The 2024 Canton Fair, a gathering of industry leaders and innovators, has invited over 200 overseas buyer groups from key "Belt and Road" countries. With an expected order demand of over US$1.35 billion, it promises significant business opportunities. Centered on trends, industries, applications, and opportunities, the fair will feature eight thematic forums covering diverse areas such as enterprise globalization, surface technology, and laser cleaning. Amidst the cutting-edge technologies, cold rolling forming machines and laser machines stand out. Cold rolling machines offer precise solutions for metal shaping, while laser machines revolutionize manufacturing with their precision and versatility. With 1,200+ global brand exhibitors, the fair will showcase tens of thousands of products, fostering innovation, collaboration, and business opportunities in manufacturing.

Cold roll forming equipment is a cost-effective process used to create high-quality, precision-formed metal parts. Cold roll forming equipment offers greater flexibility and adaptability compared to traditional hot roll forming processes. This technology uses cold-rolled steel, which has superior mechanical properties compared to hot-rolled steel. The cold roll forming process involves multiple stages, where the steel is repeatedly passed through sets of rolls, gradually shaping and contouring the material until the desired form and profile are achieved. The advantage of cold roll forming is that cold roll forming equipment can produce intricate shapes with tight tolerances, maintaining consistent quality and dimensional accuracy. Cold roll forming equipment also offers the benefit of being able to produce parts in high volumes with short lead times, making cold roll forming equipment suitable for mass production applications. Furthermore, cold roll forming equipment can be used to form different types of metal alloys, providing flexibility in material selection. The process is widely used in various industries, such as automotive, construction, and manufacturing, to produce parts like metal panels, profiles, and structural components.

Security packing, nice packing are more necessary for all the sales of various industries. Full automatic or Semi automatic packing machines are improving products transportation safety.

Advanced solutions including high frequency pulse welder technology, PCB interconnect welding processes, heat pulse control system integration, spot welding copper to copper capability, and precision spot welding pneumatic controller design deliver stable energy control, consistent weld quality, and efficient production for modern electronics and high-conductivity metal joining applications.

Integrated resistance welding system with precise current monitoring ensures stable, repeatable weld quality. Designed for aluminum welding, automotive body spot welding, mesh panel production, and parallel butt welding. Delivers high efficiency, strong joints, reduced defects, and reliable performance for automated industrial manufacturing environments.

Advanced manufacturing relies on the best capacitor discharge welder for battery tab welding, intelligent systems competing with Miyachi controllers, and integrated weld inspection instrument monitoring. From Automotive nut and bolt projection welding to precision work using a spot welding machine for stainless steel, these solutions ensure stable quality, efficiency, and automation readiness.

Precision manufacturing benefits from spot welding thermocouple wires, stable resistance welding machine price, and accurate inverter resistance welder monitor control. Using an automated pulse welder and understanding capacitor discharge welding process explanation ensures consistent, high-quality welds. This integrated approach boosts efficiency, repeatability, and reliability across modern industrial and automotive production lines.