- Home

- >

News

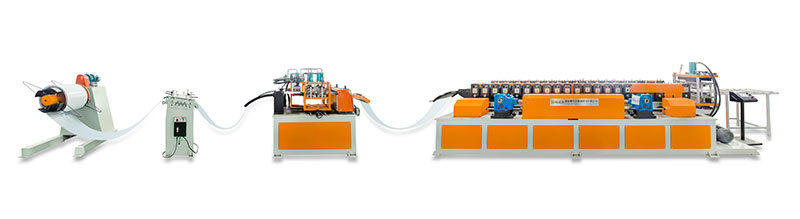

The cold roll forming machine offers distinct advantages and characteristics. Its precision engineering ensures accurate shaping of metal sheets into intricate profiles, enhancing product quality and structural integrity. Versatility is a key feature, allowing customization for various material thicknesses, widths, and specific profile requirements. Automation enhances efficiency, reduces waste, and minimizes downtime, contributing to cost savings and faster turnaround times. Environmental benefits, including lower energy consumption and minimal waste, make it a sustainable manufacturing solution.

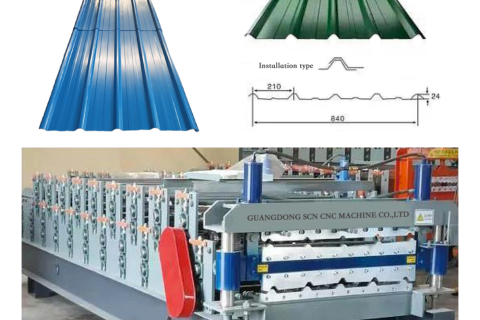

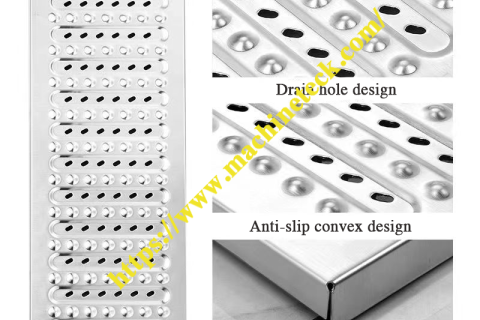

Cold roll forming equipment is a cost-effective process used to create high-quality, precision-formed metal parts. Cold roll forming equipment offers greater flexibility and adaptability compared to traditional hot roll forming processes. This technology uses cold-rolled steel, which has superior mechanical properties compared to hot-rolled steel. The cold roll forming process involves multiple stages, where the steel is repeatedly passed through sets of rolls, gradually shaping and contouring the material until the desired form and profile are achieved. The advantage of cold roll forming is that cold roll forming equipment can produce intricate shapes with tight tolerances, maintaining consistent quality and dimensional accuracy. Cold roll forming equipment also offers the benefit of being able to produce parts in high volumes with short lead times, making cold roll forming equipment suitable for mass production applications. Furthermore, cold roll forming equipment can be used to form different types of metal alloys, providing flexibility in material selection. The process is widely used in various industries, such as automotive, construction, and manufacturing, to produce parts like metal panels, profiles, and structural components.

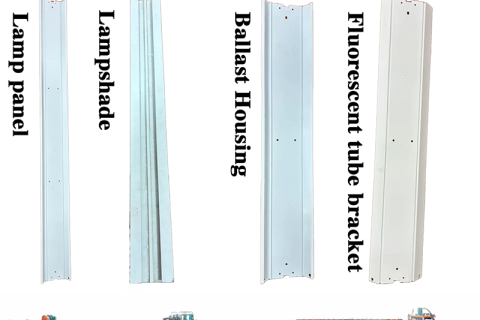

A variety of metal processing equipment: spot welding, cable trays, C/U/Z steel forming, tiles and cold rolling forming, which are used in the fields of automobiles, electricity, construction, etc., are characterized by high efficiency and precision, meet diversified processing needs, and promote the upgrading of modern industrial manufacturing.

The new factory moved and the space increased three times. It focuses on the manufacturing of cold forming machines and production lines, including fire doors, hanging board lines, compact shelving automation lines, etc. It has leading technology, improved production efficiency, met market demand, continued innovation, and served global customers.

1:High processing precision and stable forming. 2:Low energy consumption and efficient production. 3:The material is widely adaptable and the surface quality is good. 4:The structural design is reasonable and the economic benefits are significant.