- Home

- >

News

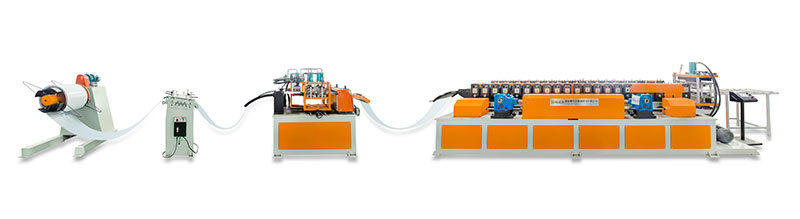

Cold roll forming equipment is a cost-effective process used to create high-quality, precision-formed metal parts. Cold roll forming equipment offers greater flexibility and adaptability compared to traditional hot roll forming processes. This technology uses cold-rolled steel, which has superior mechanical properties compared to hot-rolled steel. The cold roll forming process involves multiple stages, where the steel is repeatedly passed through sets of rolls, gradually shaping and contouring the material until the desired form and profile are achieved. The advantage of cold roll forming is that cold roll forming equipment can produce intricate shapes with tight tolerances, maintaining consistent quality and dimensional accuracy. Cold roll forming equipment also offers the benefit of being able to produce parts in high volumes with short lead times, making cold roll forming equipment suitable for mass production applications. Furthermore, cold roll forming equipment can be used to form different types of metal alloys, providing flexibility in material selection. The process is widely used in various industries, such as automotive, construction, and manufacturing, to produce parts like metal panels, profiles, and structural components.