- Home

- >

News

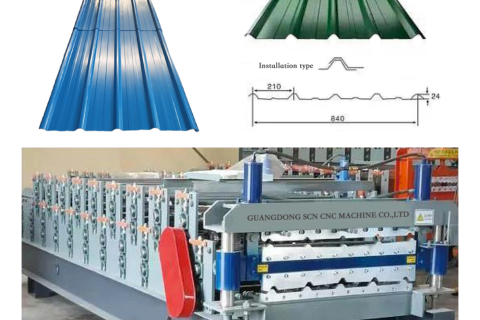

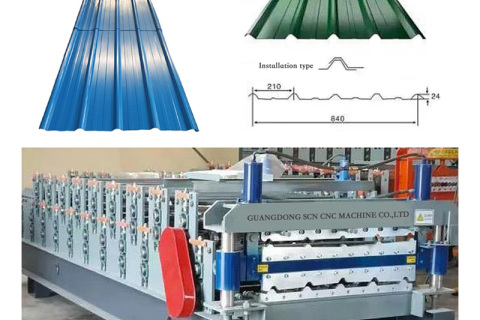

The cold roll forming machine offers distinct advantages and characteristics. Its precision engineering ensures accurate shaping of metal sheets into intricate profiles, enhancing product quality and structural integrity. Versatility is a key feature, allowing customization for various material thicknesses, widths, and specific profile requirements. Automation enhances efficiency, reduces waste, and minimizes downtime, contributing to cost savings and faster turnaround times. Environmental benefits, including lower energy consumption and minimal waste, make it a sustainable manufacturing solution.

Spanish customers inspected our roll forming machine and appreciated its high efficiency, precision, energy saving and environmental protection advantages. They look forward to deepening cooperation and creating a better future.

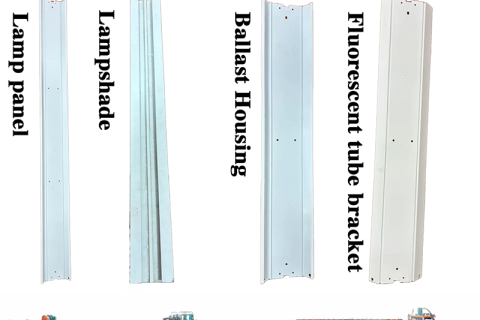

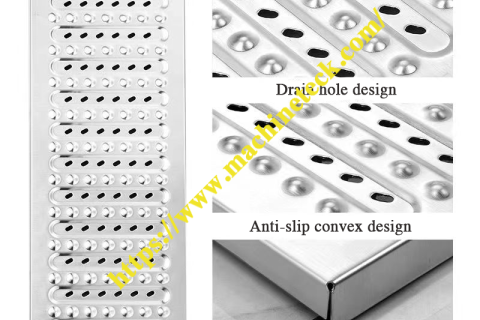

A variety of metal processing equipment: spot welding, cable trays, C/U/Z steel forming, tiles and cold rolling forming, which are used in the fields of automobiles, electricity, construction, etc., are characterized by high efficiency and precision, meet diversified processing needs, and promote the upgrading of modern industrial manufacturing.

1:High processing precision and stable forming. 2:Low energy consumption and efficient production. 3:The material is widely adaptable and the surface quality is good. 4:The structural design is reasonable and the economic benefits are significant.