industrial spring kielce poland for welding power supply manufacturer

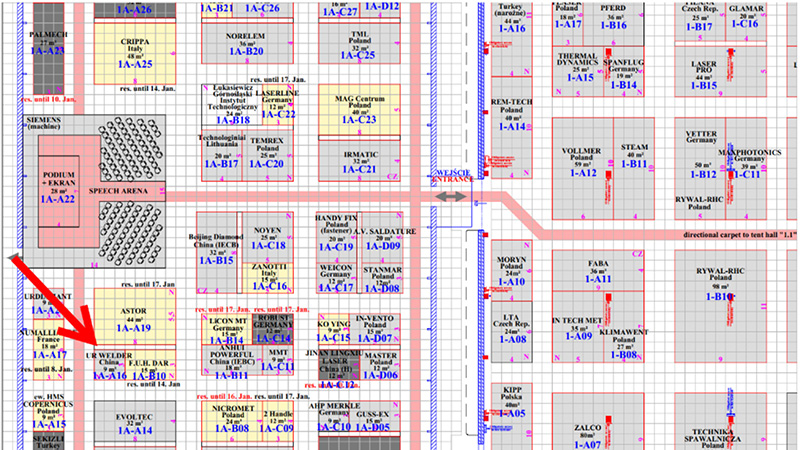

2025-01-17 11:59NDUSTRIAL SPRING KIELCE POLAND (25-28.03.2025)

STOM-TOOL - BLECH & CUTTING - LASER - ROBOTICS - FIX, Welding, Expo-Surface, Fluid Power, Control-Stom, 3D Printing Days

The International Welding Technology and Equipment Exhibition in Poland is held every spring at the Kielce Tagy Exhibition Center and is an important event in the global welding industry. The exhibition brings together welding technologies and equipment from all over the world, showcases the latest innovative products and solutions, and provides a platform for communication and cooperation for industry experts and companies. As China's leading and powerful welding power supply manufacturer, Huandian will participate in this exhibition and showcase our latest core products and intelligent solutions.

IDP series precision welding power supply-technology leading the industry

The IDP series precision welding power supply is a high-frequency inverter DC power supply independently developed by Huandian Company. Welding machine power supply uses imported high-quality components to ensure the stability and reliability of the product. This series of welding power supplies combines advanced inverter technology and DSP electronic control technology, and has many significant features:

1. Precise control and high stability

The control accuracy of the IDP series welding power supply is as high as 0.2 milliseconds, which can achieve extremely precise welding control. Its low heat generation and small workpiece damage make the welding process more stable, the welding point has a smooth appearance and high strength, which is suitable for precision welding needs.

2. Intelligent monitoring and data traceability

This series of products supports real-time welding data monitoring, such as current, voltage, power, pressure, displacement, etc., to ensure the quality control of the welding process. At the same time, welding power source is equipped with a welding quality traceability function, which can record and analyze welding data to ensure the consistency and reliability of welding quality.

3. Welding pre-inspection and electrode grinding function

The IDP series supports current pre-inspection before welding, which effectively avoids electrode damage and poor welding. In addition, the built-in electrode grinding function can set the number of electrode uses, and automatically alarm after reaching the set number, reminding the user to grind the electrode to ensure the effect of each welding.

4. Innovative servo motor control

The industry's first servo motor control technology can accurately adjust the welding pressure and welding head reset distance to avoid the impact force generated by traditional cylinder welding, especially in the projection welding process.

5. Breakthrough inverter frequency technology

The IDP series welding power source supports free switching of welding frequency from 1kHz to 5kHz, which can better adapt to different welding process requirements, provide higher control accuracy and faster response speed than similar products, and further improve welding quality.

Highlights and prospects of the exhibition

At this Polish International Welding Technology and Equipment Exhibition, Huandian will showcase our innovative products and have in-depth exchanges with global customers and industry experts. Through continuous innovation and technological breakthroughs, we are committed to providing efficient, stable and intelligent welding solutions to global customers and promoting the development and application of industry technology.

If you are interested in learning more information, please contact us. We look forward to meeting you at the exhibition to discuss the development trend of future welding technology.