Outlook for resistance welding power supply industry in 2025: intelligence, efficiency and greening

2025-02-17 19:13With the arrival of 2025, the welding equipment industry is ushering in a series of innovations and changes. Keywords such as precision resistance welding power supply, large-function DC inverter welding power supply, spot welding machine, transformer welder and welding monitor reveal the main development trends of this industry.

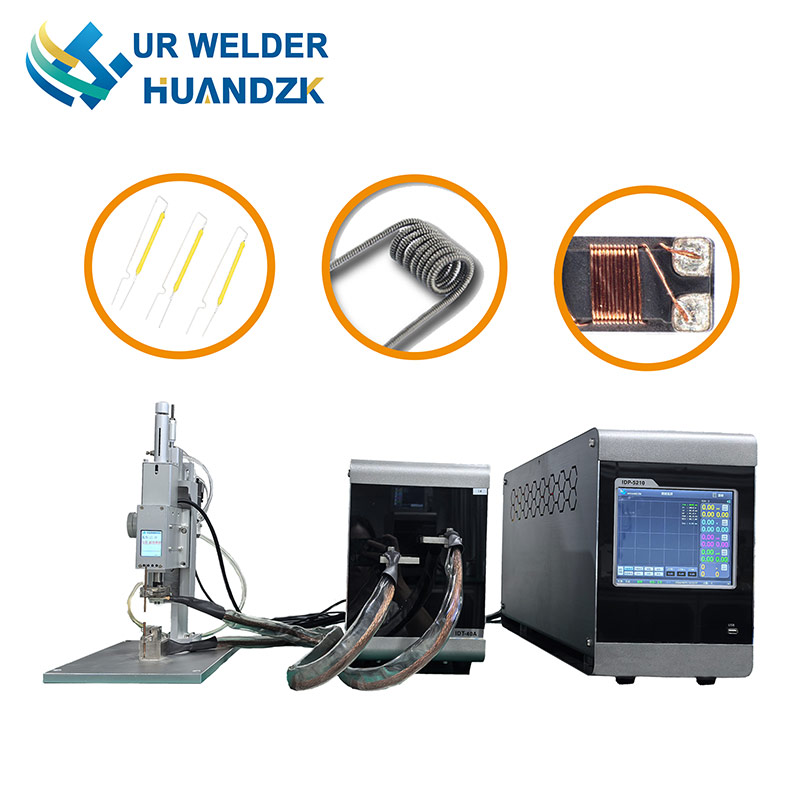

With its high precision and stability, precision resistance welding power supply has shown great potential in high-end manufacturing fields such as aerospace and automobile manufacturing. With the continuous improvement of the manufacturing industry's requirements for welding quality, the market demand for precision resistance welding power supply will continue to grow. At the same time, the application of large-function DC inverter welding power supply is also becoming more and more extensive. Inverter power supply technology has promoted the refinement and intelligent development of welding technology with its advantages of high efficiency, energy saving, small size and light weight.

Spot welding machine, handwheel rolling and welding machine, wire butt welding machine, as multiple different classifications of resistance welding, have an indispensable position in industries such as automobile manufacturing and home appliance production. With the popularization of new energy vehicles and the intelligent upgrading of home appliances, the market demand for spot welding machines will further expand. As an important means of welding quality control, the market size of welding monitors is also expanding. The wide application of products such as laser welding monitors and fiber grating sensors reflects the continuous progress of welding monitoring technology.

Overall, the welding equipment industry is developing in the direction of high efficiency, intelligence and greenness. Technological innovation and industrial upgrading have become key factors driving this trend. With the application of new technologies such as 5G, Internet of Things, and artificial intelligence, welding equipment will achieve more intelligent operation and remote monitoring, improve production efficiency and welding quality. At the same time, green environmental protection will become an important development direction of the welding equipment industry. Enterprises need to actively develop green welding equipment that meets environmental protection standards to reduce energy consumption and environmental pollution.

Looking to the future, the welding equipment industry will continue to maintain an active development trend and provide strong support for the high-quality development of the manufacturing industry. Enterprises need to keep up with the trend of technological development, increase R&D investment, and enhance independent innovation capabilities to meet future market challenges.