Ur Welder to unlock ASEAN Industry 4.0 with smart welding technology in Hanoi Vietnam

2025-04-26 16:53Guangdong Ur Welder Co., Ltd. will present its intelligent welding solutions at the 2025 Hanoi Industrial Machinery Exhibition in Vietnam

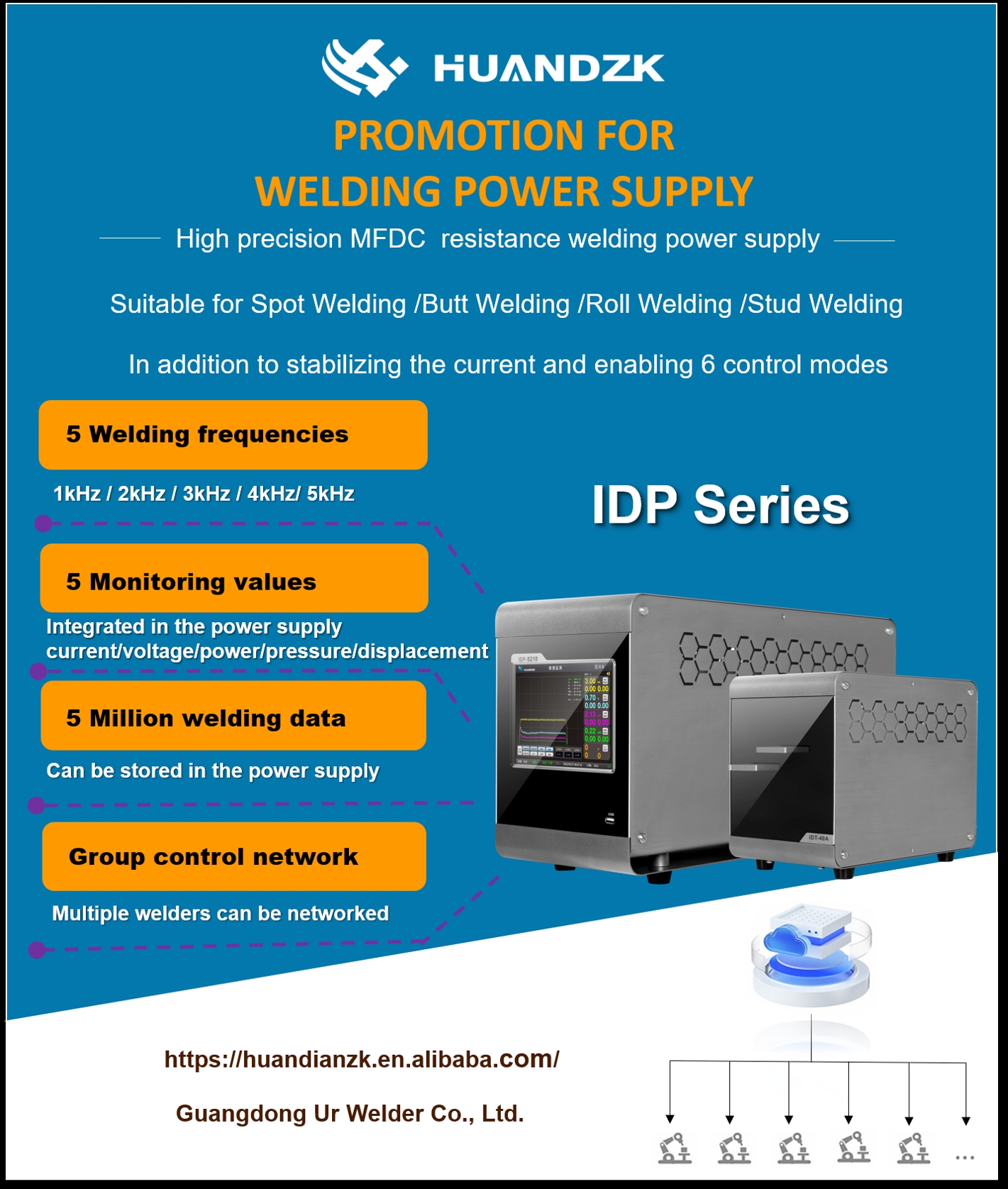

From May 14 to 16, 2025, the Hanoi International Convention and Exhibition Center (ICE) in Vietnam will usher in the annual industrial event - the Hanoi Industrial Machinery and Machine Tool Metalworking Exhibition (VINAMAC EXPO). As a leading company in the field of precision resistance welding, Guangdong Ur Welder Co., Ltd. will present its IDP series, IDW series, IAW series intelligent welding power supplies and full-link digital welding solutions, demonstrating the innovative strength of China's smart manufacturing to the global manufacturing industry.

Core product matrix: precise empowerment of Industry 4.0

The IDP series high-frequency inverter DC welding power supply exhibited this time uses all imported components and DSP electronic control technology, supports free switching of welding frequencies from 1kHz to 5kHz, and has a control accuracy of 0.2 milliseconds. DC welding power supply unique "pressure trigger + displacement penetration" dual closed-loop control function can ensure that the weld penetration consistency error is less than 0.05mm, which is particularly suitable for high-precision welding scenarios such as new energy vehicle battery trays and aviation sheet metal parts.

The IDW series medium frequency inverter welding power supply focuses on the new energy track, equipped with six control modes such as constant peak current and constant power, which can adapt to the micro-welding needs of special materials such as copper and aluminum dissimilar metals and enameled wires. The IAW series robot welding controller can display 8 waveform curves such as welding current, voltage, and resistance in real time with a 7-inch high-definition touch screen and oscilloscope function, providing visual data support for welding process optimization.

Digital welding ecology: quality and efficiency leap from single machine to cluster

The welding quality monitor exhibited by Guangdong Ur Welder Co., Ltd. supports cloud storage and USB flash drive export of 5 million welding data, and can automatically detect parameter deviations such as welding current and pressure, with a defect detection rate of 99.98%. Welding quality monitors welding group control system breaks through the traditional single-machine operation mode and supports mainstream industrial protocols such as Modbus TCP/IP and EtherNet/IP. Welding quality monitor can realize the simultaneous release of parameters of multiple welding machines, real-time monitoring of production progress, and dynamic optimization of energy consumption, helping enterprises reduce manual intervention costs by more than 30%.

As a national-level flagship exhibition of Industry 4.0 approved by the Prime Minister of Vietnam, VINAMAC EXPO attracted more than 350 enterprises from more than 20 countries around the world to participate in the exhibition. The intelligent welding solutions exhibited by Guangdong Ur Welder Co., Ltd. are not only a centralized review of China's high-end equipment manufacturing technology, but also provide a feasible technical path for the digital transformation of Vietnam and even ASEAN's manufacturing industry.