What materials are suitable for spot welding machines?

2024-10-26 11:36Spot welding, also known as precision resistance welding machine technology, is a welding process with a long history but is timeless. Inverter spot welder uses extraordinary skills to seamlessly fuse two or more metal plates without any filler materials. Only the clever combination of current and heat can weave an indestructible connection in the metal world.

In the mystery of this process, copper alloy electrodes play a vital role. They not only closely contact with the metal plates and apply just the right pressure, but also act like a magician's wand, guiding the current to shuttle between them and stimulate hot sparks. This heat generated by the current is the essence of the spot welding process. Control for resistance spot welding melts the metal in an instant and solidifies under the continuous pressure of the electrode to form a solid molten joint, as if time has solidified at this moment, witnessing the silent understanding and fusion between the metals.

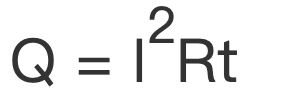

Heat, a key element in the welding process, is generated by the exquisite combination of current, resistance and power-on time. Among them, "Q" represents heat energy, "I" is current, "R" is resistance, and "t" is the duration of power on. Together, they weave the thermal equation of the spot welding process and provide just the right amount of energy for each welding.

In terms of material selection, spot welding has shown its wide adaptability. Low-carbon steel, with its low thermal conductivity and high resistance, has become the best partner for spot welding. However, for steel with high carbon content, spot welding also shows its flexibility. By adjusting the electrode tip or current voltage, it can easily cope with it, showing the infinite possibilities of spot welding. Even special materials such as aluminum alloy can achieve perfect fusion under the magic of spot welding, further broadening the application field of this process.

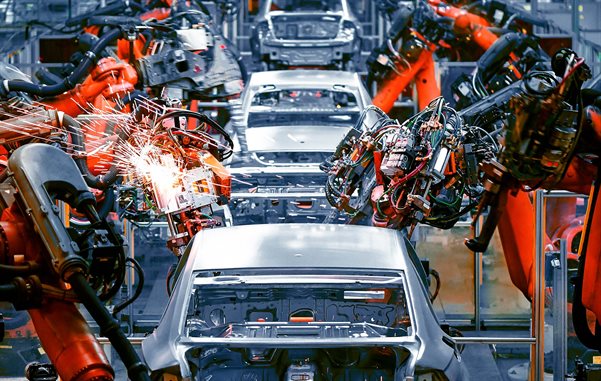

Auto spot welding machines are active in many fields such as chip manufacturing, automotive industry, aerospace, home appliance manufacturing, metal furniture, electronics industry, medical equipment, etc., becoming a bridge connecting the future and reality. Especially on automated production lines, auto spot welding machine technology is like a duck in water. With its easy-to-automate characteristics, hand spot welder has become an indispensable part of mass production. In the field of automobile manufacturing, copper spot welder has become the first choice for body welding technology with auto body spot welder's high efficiency, stable and reliable welding quality, safeguarding the safety and quality of every car.

Spot welding, a welding process that combines ancient wisdom and modern technology, is writing a new chapter in metal connection with chinese spot welder's unique charm.