- Home

- >

News

Current detection of precision spot welding machines is the key to ensuring welding quality. Oscilloscope testing may not be accurate, so it is recommended to use a dedicated current tester for monitoring. When purchasing, companies should choose equipment equipped with a current tester and conduct regular testing and calibration to ensure the stability and reliability of welding quality.

The resistance spot welding machine is equipped for resistance seam welding, utilizing resistance welding electrodes.

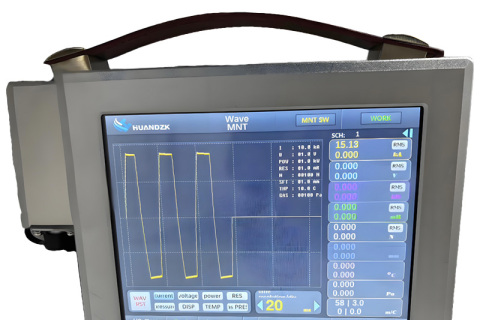

IDP series inverter DC welding power source, as a masterpiece independently developed by Huandian, integrates high-frequency inverter and advanced DSP control technology. The core components are selected from imported components to ensure the excellent performance and long-term durability of the product. Its high-precision control system (accuracy up to 0.2 ms), low-heat design, micro-damage treatment of workpieces, beautiful weld appearance, strong welding tension