Automatic feeding nut spot welding machine leads the new trend of industrial manufacturing

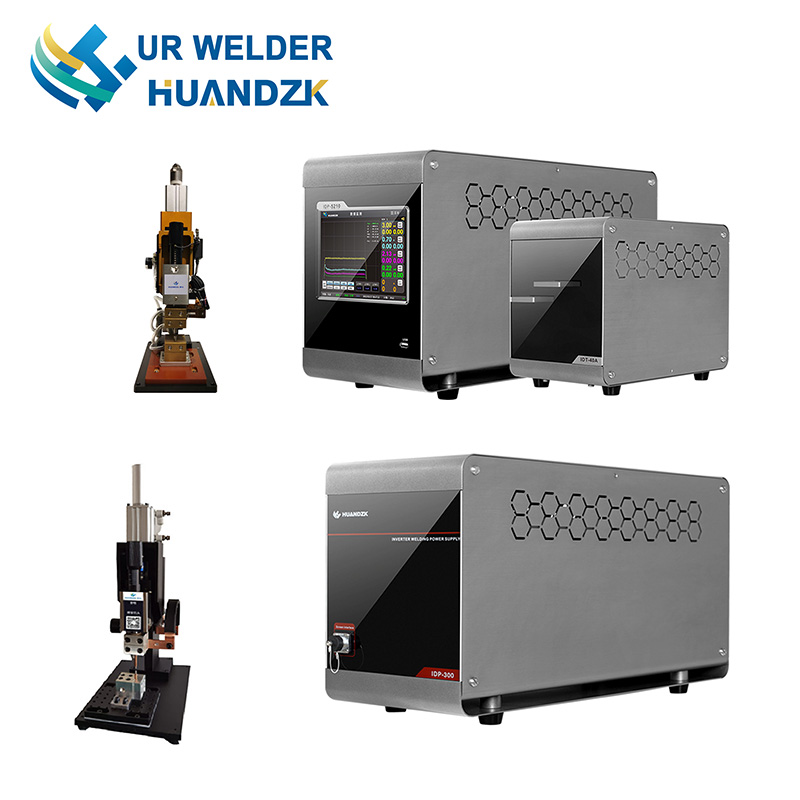

2025-03-18 12:45Use and maintenance of nut spot welding machine. Nut spot welding machine is a machine used for automatic welding of nuts and bolts. Nut spot welding machine adopts the pulse control principle and consists of feeding mechanism, clamping mechanism, transmission mechanism and other parts.

Automatic spot welding nut machines characteristics are: small size, easy operation and high efficiency. Suitable for large-scale product processing and maintenance. Screws are one of the most widely used fasteners in industry, with various types and specifications. Due to different uses, the requirements for screws are also different;

Some require high hardness, strong wear resistance and corrosion resistance and are used in important occasions; some require low cost and long life and are used in industries such as home appliances and furniture; others require anti-loosening and anti-slip, etc.! So for these situations, we need to use a variety of different screw equipment!

Working principle

The automatic feeding nut spot welding machine works on the principle of resistance heat, using instantaneous high current to make the contact surface of the nut and the workpiece melt at high temperature, and then cool to form a firm weld. The feeding system transports the nuts to the welding position through vibration sorting, pneumatic or vacuum adsorption to achieve automated operation.

Advantages of nut spot welding machine

High efficiency and precision advantages: The automatic feeding spot welding machine for nuts has the characteristics of high efficiency and precision. Spot welding nut machine's automatic feeding system (vibration plate or pneumatic) can achieve the delivery of 5-40 nuts per minute, and can carry out multi-point welding simultaneously in the welding cycle.

Safe and reliable guarantee: The spot welding machine is safe and reliable, which can avoid the risk of crushing caused by manual placement. At the same time, spot welding nuts is equipped with a detection feedback mechanism to ensure that welding is started only after the nut is in place.

Stable quality characteristics: Spot welding nuts's quality is stable, and automatic nut spot welding machine uses medium frequency inverter technology to provide DC current to make the weld penetration uniform and the thread will not deform.

Wide range of applications: This spot welding machine has a wide range of applications and is compatible with M4-M22 nuts and a variety of materials, such as carbon steel, stainless steel, galvanized sheet, etc.

Energy-saving and durable characteristics: The equipment is energy-saving and durable. Compared with traditional AC welding machines, the energy saving range is more than 60%, the service life of the electrode is extended, and the maintenance cost is low.

Automatic feeding nut spot welding machines are widely used in automotive, aerospace, electronics and rail transportation. In automobile manufacturing, projection nut welding machine efficiently welds nuts of doors, chassis and other structural parts to ensure driving safety; in the aerospace field, automatic nut spot welding machine accurately fixes aircraft engine brackets and skin parts to meet the needs of extreme environments; in the electronics manufacturing industry, nut spot welding machine firmly connects tiny parts of communication equipment and medical devices to improve product reliability; in the rail transportation field, spot welding nut machine quickly welds train carriages, bogies and other parts to ensure transportation efficiency and safety. Nut spot welding machine's efficient and accurate automated welding technology has become a powerful assistant for modern industrial manufacturing.