What are the functions of spot welding electrodes in spot welding machine construction?

2024-10-28 13:59Spot welding machine, as an indispensable precision welding equipment in modern industry, its structural design and functional realization contain a high degree of scientific and technological wisdom. The equipment is mainly composed of three core components: spot welding head, spot welding power supply and transformer. The three work together to create a stable and efficient welding process.

As the direct executor of the welding operation, the spot welding head is flexible and changeable in design, and can be accurately selected and adjusted according to the needs of workpieces of different materials, thicknesses and shapes. The spot welding power supply is like the intelligent brain of the accurate spot welding machine, accurately regulating the output of current, voltage and heat to ensure that every welding can achieve the best effect.

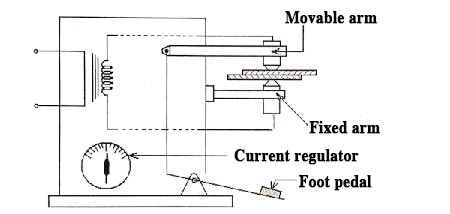

In-depth exploration of the internal structure of the roller spot welding machine, it is not difficult to find its exquisiteness. The two electrodes (one is a fixed arm and the other is a movable arm), one static and one moving, are like wings guarding the welding quality. The fixed arm is as stable as a mountain, providing solid support for the welding process; the movable arm is flexible and can be accurately moved and adjusted according to the welding needs. The power supply system continuously injects energy into the welding process to ensure the stability of the welding operation. The hydraulic or pneumatic control system is like a precise commander, regulating the movement and pressure of the electrode to ensure the accuracy and stability of the welding.

In the magical world of resistance welding, the resistance spot welding electrodes plays an important role. It not only carries the high current required for fusion, but also transmits a strong mechanical force to make the welding plates fit tightly under strong pressure, and also maintains the precise alignment of the welding plates during the fusion process. In addition, the electrode is also like a smart thermostat, cleverly helping to eliminate excess heat in the welding area, avoiding overheating or over-melting, and ensuring flawless welding quality. With these exquisite designs and excellent performance, the capacitor discharge spot welding machine has become an indispensable welding tool in modern industry.