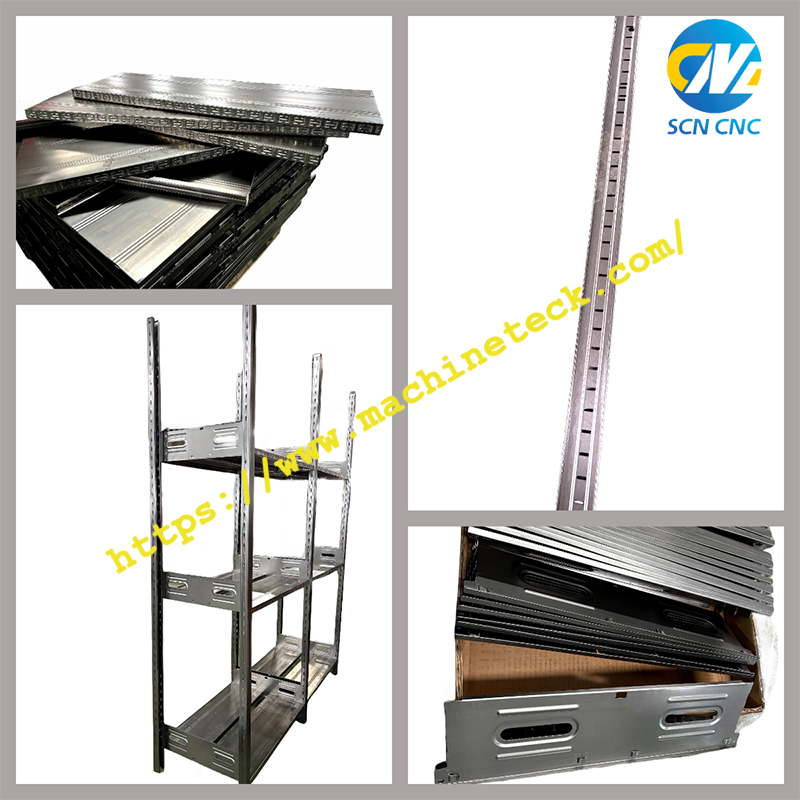

Integrated Shelves: High-Precision Cold Roll Forming Machine for Efficient Rack Production

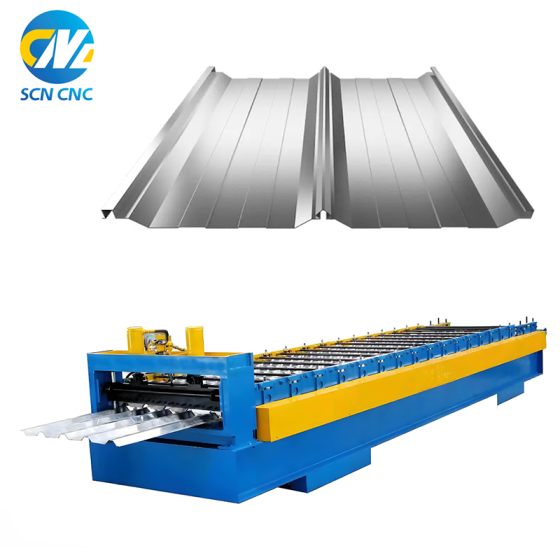

A cold roll forming machine, is designed to bend metal sheets or strips without the need for heat. Its functionality lies in shaping metal through a series of rollers, gradually forming the desired profile. This process offers several advantages, including precise shaping, minimal material waste, and the ability to work with a variety of metals, including steel, aluminum, and copper. Its key features include adjustable roller configurations for different profiles, high precision, and automation capabilities for efficient production. Cold bending machines are widely used in industries such as construction, automotive, and manufacturing for producing components like roofing panels, studs, and frames.

- Scn cnc

- Guangdong,China

- 30 days

- 100 sets per year

- Information

The cold roll forming machine is a comprehensive solution for the production of integrated racks, boasting a seamless process that combines punching, roll forming, and assembly. This machine stands out as a testament to advanced engineering and precision manufacturing, designed to cater to the diverse needs of the storage industry.

The cold roll forming machine

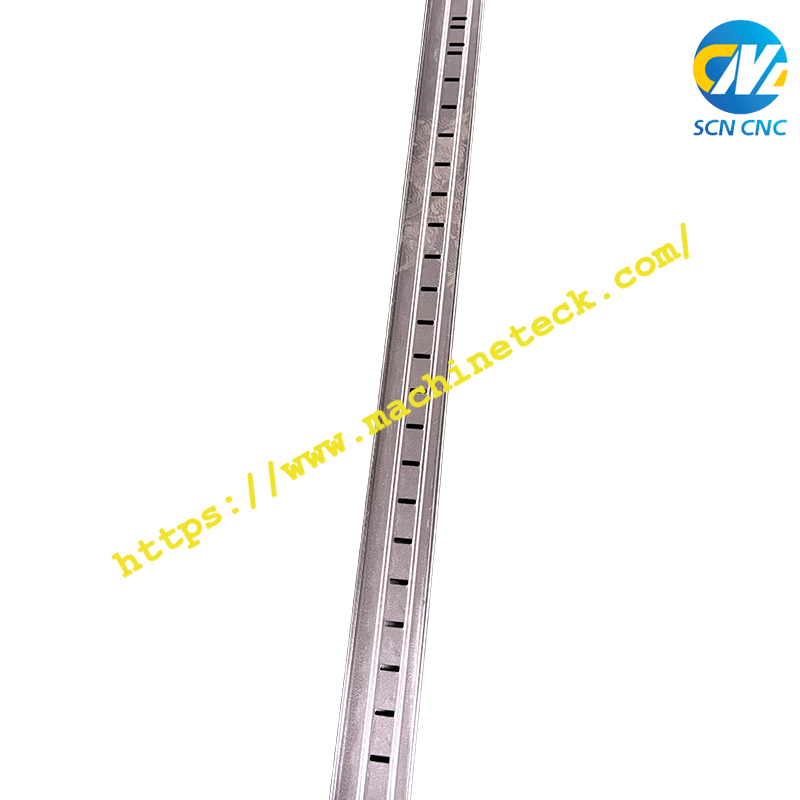

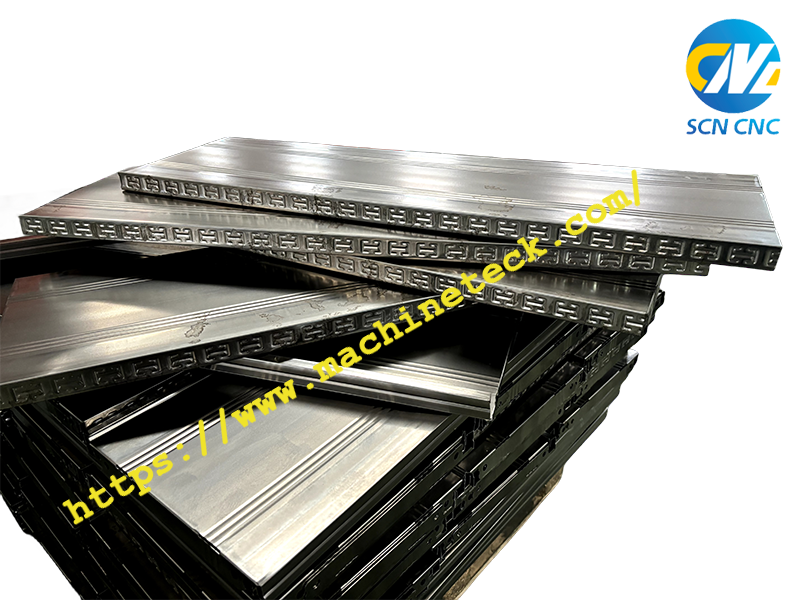

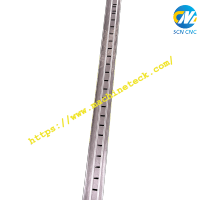

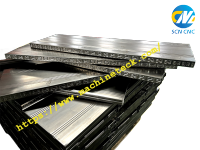

One of the key advantages of the cold roll forming machine is its ability to produce racks with exceptional precision and repeatability. The cold forming process ensures that the components, including the upright columns, hanging boards, and shelving boards, are formed with utmost accuracy, maintaining a uniform shape and dimensions throughout. This ensures a secure and stable rack structure that can withstand the rigors of daily use.

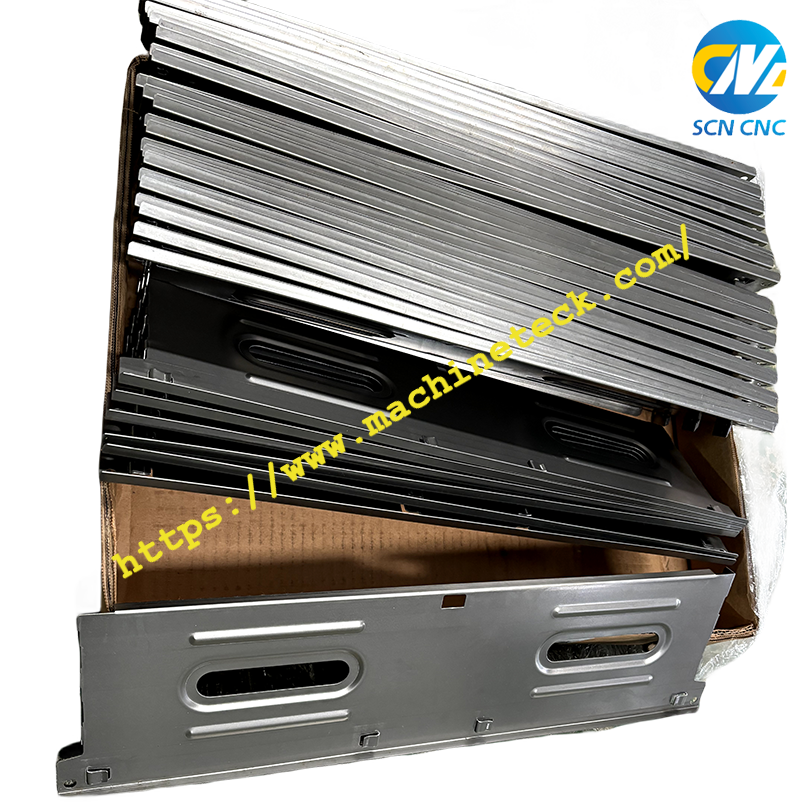

Moreover, the machine's integrated punching capabilities add another layer of convenience. It can punch holes and cutouts in the components with ease, allowing for the attachment of accessories or the creation of customized storage solutions. This flexibility means that the racks can be tailored to fit specific storage needs, whether it's for a warehouse, retail store, or any other industrial setting.

The cold roll forming machine is also renowned for its high production efficiency. With its automated processes and advanced controls, it can quickly and efficiently produce racks in large quantities, meeting the demands of even the busiest manufacturing lines. This not only saves time but also reduces labor costs, making it a cost-effective investment for any business.

Additionally, the machine's robust construction and durable components ensure its longevity and reliability. It is built to withstand the rigors of continuous operation, making it a dependable asset for any manufacturing operation.

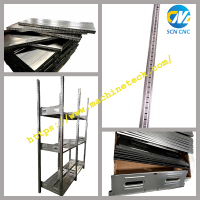

The cold roll forming machines can be used to produce upright columns, hanging boards, and shelf boards. Upright columns, hanging boards and shelving boards can be assembled into shelves, providing excellent stability and versatility in this comprehensive storage solution, making it very suitable for various applications. With its sturdy structure and modular design, it is easy to assemble and customize to meet your specific storage needs.

Finally, the cold roll forming machine is an exceptional piece of equipment that offers precision, flexibility, and efficiency in the production of integrated racks. Its ability to produce high-quality racks with customized features, combined with its high production capacity, makes it a valuable addition to any business seeking to enhance its storage capabilities.

Most of the time, our wire forming machine technical engineers in debugging products, often one step difference, will lead to the equipment produced by the product is not stable, and the accuracy can not meet the requirements. At this time, the adjustment machine master needs to calm down, find the reason and solve the problem. What are the main reasons for the unstable production of the product...more