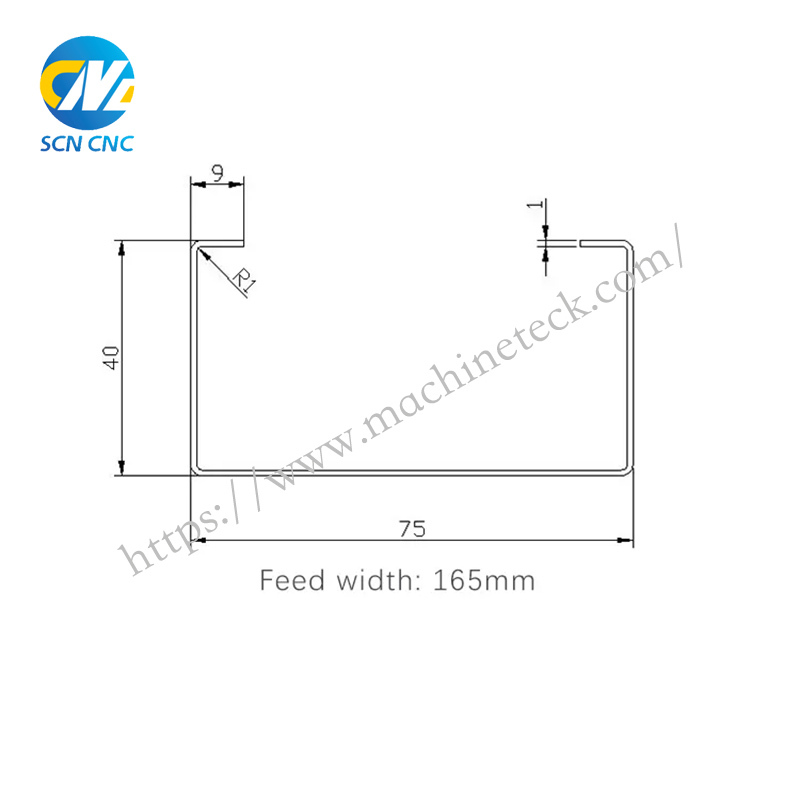

Semi Automatic Cold Metal C Channel Purlin Roll Former Shelf Column Forming Machine

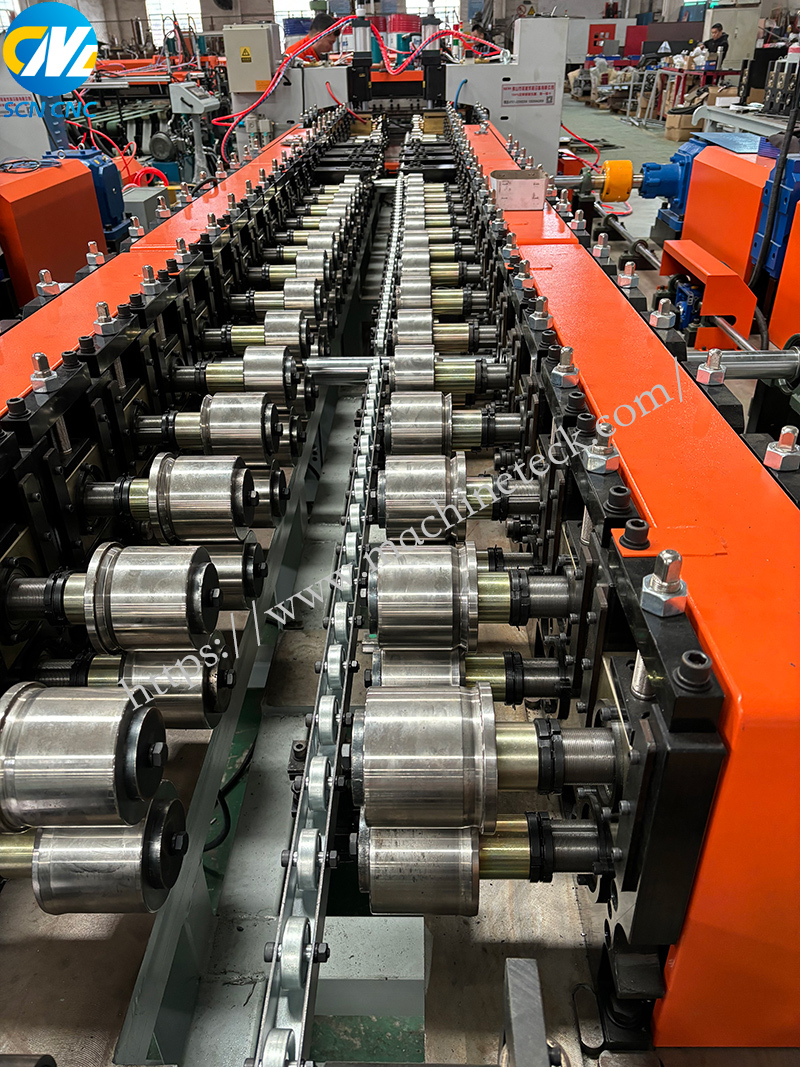

Efficiency: The cold bending machine adopts a continuous processing method to improve production efficiency.

High precision: The cold bending forming machine adopts a precise roller design and control system, which can ensure high dimensional accuracy and accurate shape of the processed metal parts.

Wide application range: The cold bending forming machine can process various metal sheets of different materials and thicknesses.

Environmental protection and energy conservation: The cold bending forming machine does not require heating during the processing.

Easy to operate and maintain: Adopting an automated control system, the operation is simple, and the equipment structure is simple, making maintenance convenient

- SCN

- Guangdong,China

- 20days

- 4sets per month

- Information

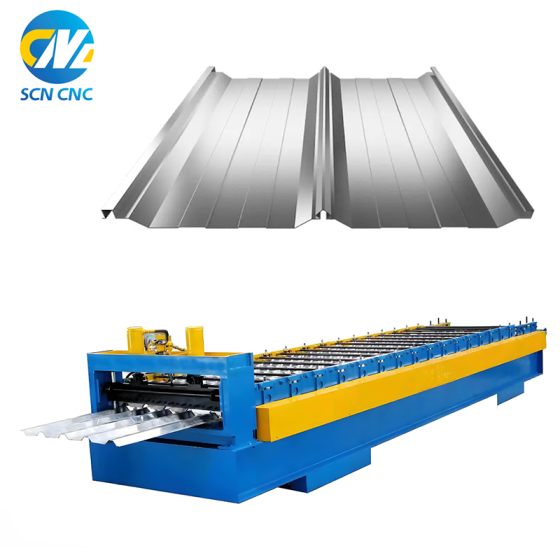

The Cold Roll Forming Machine is a versatile and efficient piece of equipment designed for the production of various building materials. It is widely used in building material shops, manufacturing plants, machinery repair shops, and construction works. This machine is specifically designed to transform flat metal sheets into desired shapes and profiles through a continuous cold roll forming process.

Key Features:

1. High Precision and Efficiency: The Cold Roll Forming Machine utilizes advanced technology and precision engineering to ensure accurate and consistent shaping of metal sheets. The cold roll forming machine operates at high speeds, allowing for efficient production and increased productivity. With its precise control system, this machine delivers high-quality results with minimal waste.

2. Versatility in Profile Design: This machine is capable of producing a wide range of profiles and shapes to meet various construction needs. The gutter roll forming machine can be used for manufacturing upright columns, gutter systems, roofing iron sheets, and more. The flexibility in profile design allows for customization and adaptation to specific project requirements.

3. Easy Operation and Maintenance: The Cold Roll Forming Machine is designed with user-friendliness in mind. The cold roll machine features an intuitive control panel that enables operators to easily set parameters and monitor the production process. Additionally, the machine requires minimal maintenance, ensuring smooth and uninterrupted operation.

4. Robust and Durable Construction: Built with high-quality materials and components, this machine is designed to withstand the rigors of continuous operation in demanding industrial environments. The gutter roll forming machine is engineered for durability and longevity, minimizing downtime and maximizing return on investment.

5. Safety Features: The Cold Roll Forming Machine is equipped with comprehensive safety features to protect operators and ensure safe operation. The Cold Roll Forming Machine includes emergency stop buttons, safety sensors, and protective enclosures, complying with industry safety standards and regulations.

6. Customization and Integration: This machine can be customized and integrated into existing production lines or configured as a standalone unit. The cold roll machine can be tailored to meet specific production requirements, making the cold roll machine a versatile and adaptable solution for different manufacturing setups.

In summary, the Cold Roll Forming Machine is an essential tool for the production of building materials. With its high precision, efficiency, versatility in profile design, easy operation and maintenance, robust construction, and comprehensive safety features, this machine is an ideal choice for building material shops, manufacturing plants, machinery repair shops, and construction works. Invest in the Cold Roll Forming Machine and enhance your production capabilities in the construction industry.

Main Key attributes

| Rolling thinckness | 0.3mm~3.0mm |

Voltage |

380V 3Phase 50Hz |

| Production Capacity |

20~30M/min |

Profiles | Cold Roll Forming Machine |

| Certification | CE ISO | Condition | New |

|

Supply Ability |

20Sets per Month |

Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works |

Most of the time, our wire forming machine technical engineers in debugging products, often one step difference, will lead to the equipment produced by the product is not stable, and the accuracy can not meet the requirements. At this time, the adjustment machine master needs to calm down, find the reason and solve the problem. What are the main reasons for the unstable production of the product...more