Shelf Layer Board Making Machine

1、Hydraulic Press Forming System

2、PLC Control System

3、High precision and fast speed

- SCN CNC

- Guangdong,China

- 20days

- 60 sets per year

- Information

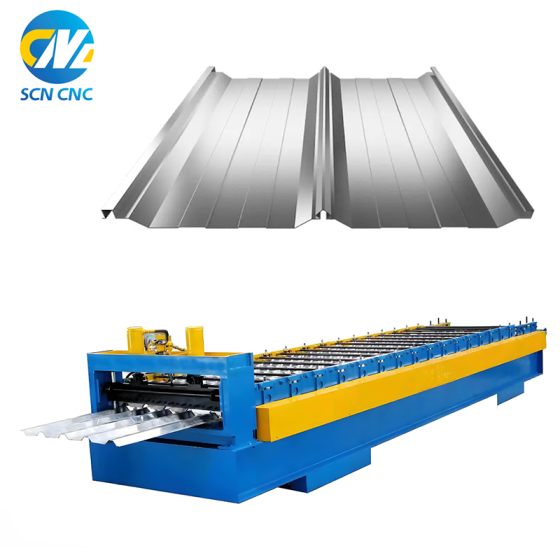

Introducing our Shelf Layer Board Machine and Racking Forming Machine for Rack Upright Shelf Frame Production

We are proud to present our advanced Shelf Layer Board Machine and Racking Forming Machine, specifically designed for the production of rack upright shelf frames. With their precision and efficiency, our machines offer a comprehensive solution for the manufacturing of high-quality and durable rack systems.

Our Shelf Layer Board Machine is equipped with cutting-edge technology, allowing for the production of shelf layer boards with precision and accuracy. With adjustable settings and a user-friendly interface, this machine can create shelf layer boards of various sizes and thicknesses to meet specific requirements. The Shelf Layer Board Machine ensures consistent and uniform results, guaranteeing the structural integrity of the rack system.

Complementing the Shelf Layer Board Machine is our Racking Forming Machine, which is designed to efficiently form rack upright shelf frames. This machine utilizes advanced forming technology and a precise control system to create the desired shape and dimensions of the rack uprights. The Racking Forming Machine ensures excellent quality and dimensional accuracy, providing a solid foundation for the rack system.

Both our Shelf Layer Board Machine and Racking Forming Machine offer exceptional efficiency and reliability. With their advanced features and high-speed operation, they can meet demanding production schedules while maintaining excellent quality standards.

Power | Motor-Pump: 7.5 - 11 kw |

Weight of machine | 6 - 7 tons |

Dimension | L=7-8m; W=1.1m; H=1.5m |

Forming speed | 20 meters/ minute - 5 meters x 4 pcs/min - 4 meters x 5 pcs/min |

Roller stations | 18 - 22 |

Transmission system | Hydraulic motor |

Profile cutting | Hydraulic cylinder |

Punching system | Hydraulic cylinder |

Control system | PLC, HMI automatic programmable |

Material thickness | 0.75 - 1.2 mm / 1.2 - 1.6 mm |

Material width | 135/ 170/ 180/ 215 mm |

Material Yield Strength | G400 - G550 Mpa (GI/PPGI, GL/PPGL) |

Most of the time, our wire forming machine technical engineers in debugging products, often one step difference, will lead to the equipment produced by the product is not stable, and the accuracy can not meet the requirements. At this time, the adjustment machine master needs to calm down, find the reason and solve the problem. What are the main reasons for the unstable production of the product...more