- Home

- >

News

Urwelder releases IDP series high-frequency inverter DC power supply, which adopts high-frequency inverter and DSP technology, 0.2 millisecond precision control, imported components to ensure stability, and is suitable for precision welding scenarios such as automobiles and 3C electronics, promoting intelligent and efficient production.

Huandian DC inverter welding power supply is efficient and stable, with high welding quality, convenient intelligent management, and guaranteed safety. Dc inverter welding power supply is suitable for high-quality welding needs, but the cost is relatively high.

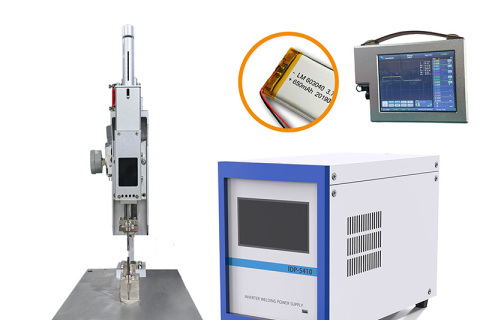

When choosing a lithium battery spot welding machine welding power supply, you need to consider the welding effect, scope of application and cost. Capacitor energy storage, inverter and AC welding power supplies each have their own advantages, suitable for different scenarios and meet diverse needs.

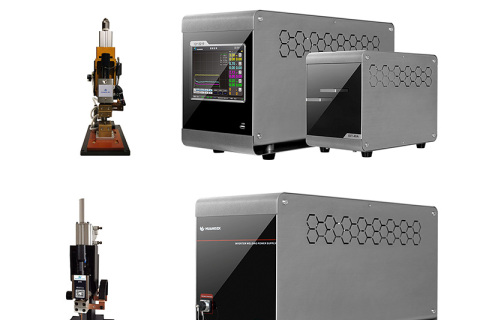

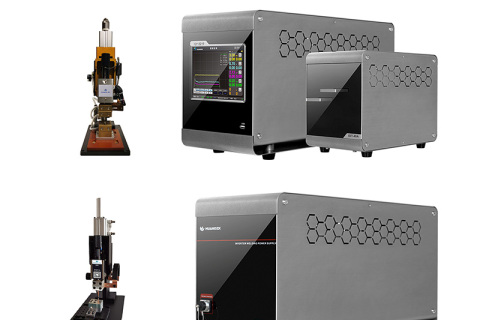

Precision spot welding machines are divided into resistive, capacitive energy storage and laser spot welding systems, suitable for different industrial scenarios. Huandian Intelligence provides energy-efficient and intelligently controlled spot welding solutions to meet the needs of new energy, 3C electronics and other industries.

China's leading welding power supply manufacturer participated in the Kielce International Welding Fair in Poland, focusing on ultra-precision, inverter, high-frequency DC welding power supplies and intelligent welding solutions, demonstrating its technological innovation capabilities.

IDP-620 welding power system is specially customized for welding of automotive parts. It features high-precision digital control, intelligent operation, stability and reliability. It is suitable for a variety of welding processes, is highly efficient and energy-saving, and has comprehensive safety protection, facilitating high-quality production.

IDP series precision welding power source is independently developed by Huandian, using imported components and advanced technology. It has the functions of welding quality control, data monitoring and traceability, high control accuracy, low heat generation, excellent solder joints, strong tension, good stability, low defect rate, and also supports networking group control and quality monitoring.

When precision spot welding machines are welding materials such as enameled wires, it is necessary to pay attention to the precise control of current and time, the importance of welding pressure, and the quality of enameled wire stripping. Our latest inverter welding power supply has a pre-welding function, which can provide reminders before welding and improve welding stability.

Ultra Precision Welding Power Supply, Precision Inverter Welding Power Supply, High Power High Frequency DC Welding Power Supply, High Frequency Welding Transformer, Welding Monitor

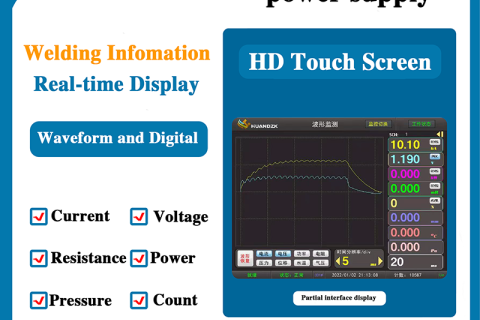

The inverter welding power supply integrates high efficiency and intelligence. Through intuitive touch screen, real-time waveform monitoring, pressure displacement control and powerful database, it realizes precise control and data analysis of the welding process, significantly improving welding quality and efficiency.

IDP series precision spot welding machines have the characteristics of high control accuracy (0.2 milliseconds), low heat generation, little damage to the workpiece, good weld appearance, high welding tensile strength, strong welding stability, and low welding defective rate. It also supports optional host computer group control and real-time welding quality monitoring system.

We craft precision welding essentials: power sources, inverters, controllers, transformers, & monitors. MF, HF, DC options available. Customizable, energy-efficient, & reliable. Boost industrial welding quality & productivity.