- Home

- >

News

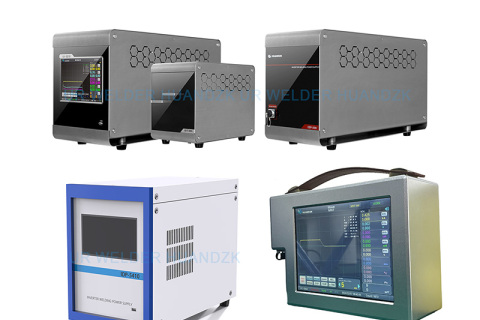

High-power inverter DC welding power source adopts advanced inverter technology, provides six control modes and five operating frequencies, ensuring stable and efficient welding process. It is widely used in automobile, shipbuilding and other fields to improve welding quality and efficiency.

IDP series inverter DC welding power supply has the advantages of high-precision control, strong welding stability, multi-stage adjustable pressure, intelligent management and multi-frequency switching, which can adapt to complex welding needs.

We will showcase its advanced IDP series precision welding power supplies at the Poland International Welding Technology and Equipment Exhibition. With precise control, intelligent monitoring and innovative technology, it will promote the development of the welding industry and provide efficient and stable intelligent welding solutions.

Inverter DC welding power source is leading the innovation of welding technology with its advantages of high efficiency, stability and energy saving. Whether inverter welding power supply is improving welding quality or extending equipment life, inverter welding power supply welding equipment has brought significant benefits to modern manufacturing industry. Choosing inverter DC welding power source is undoubtedly a wise move towards efficient welding production.

When using the copper wire spot welding machine, you need to pay attention to equipment inspection, copper wire selection, safe operation and maintenance to ensure welding quality, operational safety and stable operation of the equipment.