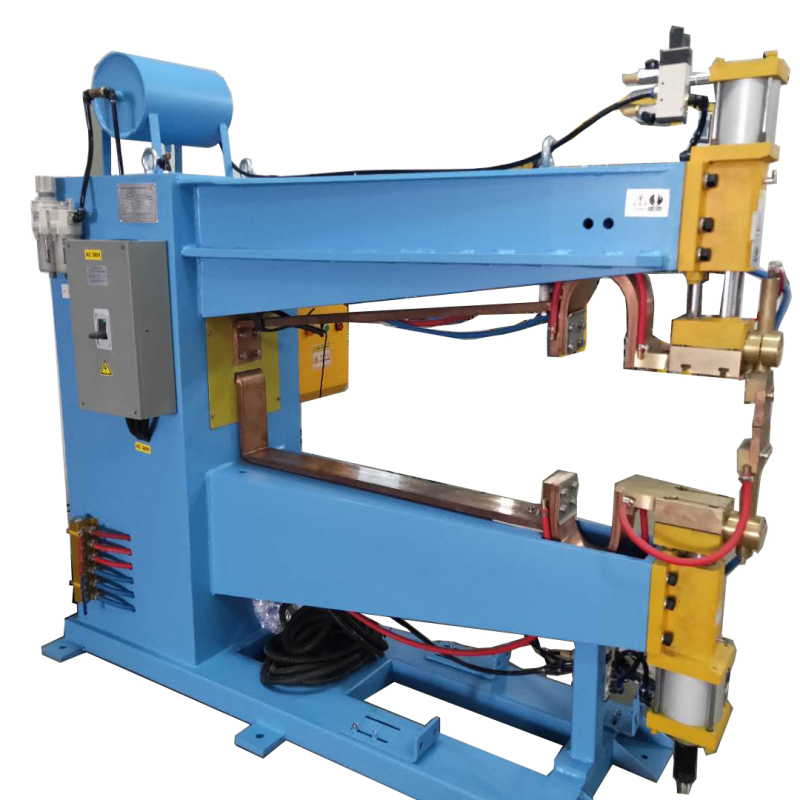

Automatic xy Table Multi Point Steel Mesh Wire Shelf Welding Machine

Feature:

1) Most Durable Spot Welding Machine

2) Most Energy Saving CNC Welding Machine

3) Most easy operative Spot Welding Machine. Our welding machines are all well bested in good condition before delivery. Once the clients receive our machines, just need connect air pressure and electronic wire, cooling water, it is ok to run.

4) Fastest Welding Machine. Capacity is important to factory. To use less labour, and more productive, our welding machines can reach your goal.

- SCN

- Guangdong,China

- 10 days

- 5 sets per month

- Information

An XY welding machine is a specialized welding system designed with precision and automation in mind. The "XY" in the name typically refers to the two-dimensional movement capability along the X and Y axes. These machines are commonly used in manufacturing and fabrication processes where accuracy, repeatability, and automated control over the welding process are crucial. Here are key features and aspects associated with XY welding machines:

Key Features:

1. Two-Dimensional Movement:

- XY welding machines are equipped with a two-dimensional movement system, allowing precise control over the positioning of the welding torch or welding head along both the X and Y axes.

2. Automated Control:

- These machines often come with automated control systems, including CNC (Computer Numerical Control) technology, which allows for programmable and repeatable welding operations.

3. High Precision:

- The XY movement system enables high precision in the welding process. This is particularly beneficial for applications where accuracy and repeatability are critical, such as in the fabrication of intricate metal components.

4. Versatility:

- XY welding machines are versatile and can be adapted for various welding processes, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and laser welding. This versatility makes them suitable for a wide range of materials and applications.

5. Programmable Weld Paths:

- Operators can program the welding paths using CNC controls, allowing for the creation of complex weld patterns and shapes. This capability is valuable for applications where precise and customized welding paths are required.

6. Increased Efficiency:

- The automated and programmable nature of XY welding machines contributes to increased efficiency in the welding process. This is especially important in high-volume production environments.

7. Reduced Operator Fatigue:

- With automated control, XY welding machines reduce the manual labor involved in welding processes. This not only increases efficiency but also minimizes operator fatigue during repetitive tasks.

Applications:

1. Automated Production Lines:

- XY welding machines are often integrated into automated production lines where precision welding is essential. They contribute to the seamless and efficient fabrication of components in industries such as automotive manufacturing and aerospace.

2. Sheet Metal Fabrication:

- In sheet metal fabrication, XY welding machines excel at joining thin metal sheets with precision. This is commonly seen in the production of automotive body components, appliances, and more.

3. Medical Device Manufacturing:

- The high precision offered by XY welding machines is valuable in the manufacturing of medical devices, where intricate welds and tight tolerances are often required.

4. Customized Welding Applications:

- Due to their programmable nature, XY welding machines are suitable for customized welding applications where specific weld patterns or shapes are needed.

XY welding machines represent a technological advancement in welding, offering precision, automation, and versatility. These machines are integral to modern manufacturing processes, providing a reliable solution for achieving high-quality welds in a variety of applications. As technology continues to evolve, XY welding machines will likely play an even more significant role in enhancing welding efficiency and accuracy.

* We have standard welding machines for AC, DC,Midium Frequency, Changle Frequency Welding Machine. 70-80% our business is customized.

* Auto Stamping Parts Welding Machines is developing well for us.

* Advanced technology keeps our welding machine with great competition among the same suppliers.

*Voltage and Currency, Welding Size are all designed per products. 2400*1500mm welding size, Wire Dia2.0--Dia10mm

The folling infor is just for your ref:We have technical data for each welding:

| Quick Details | |||||

| Condition: | New | Machine Type: | Spot Welding | Warranty: | 1 Year |

| Local Service Location: | Poland | Video outgoing-inspection: | Provided | CE Certified. | CE |

| Showroom Location: | Poland | Machinery Test Report: | Provided | Warranty of core components: | 1 Year |

| Marketing Type: | Advanced Technology 2021 | Place of Origin: | Guangdong, China | ||

| Brand Name: | Jianjin | Certification: | CCC,CE,ISO | Input Power: | 80KW |

| Voltage: | 380v | Current: | 200A | ||

| Input Voltage: | 380V,3-Phase | ||||

| Usage: | Automobile industry, sheet metal welding | ||||

| Product Name: | CNC Automatic Moving Spot Welding Machine | ||||

| Function: | welding of sheet metal | ||||

| Core Components: | PLC, Engine, Bearing, Motor, Pressure vessel | ||||

| Applicable Industries: | Machinery Repair Shops, Manufacturing Plant | ||||

| After-sales Service Provided: | Free spare parts, Field maintenance and repair service, Video technical support, Online support | ||||

| After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service | ||||

| Supply Ability | 35 Sets per Month | Different Welding Current: | 30 Kinds | ||

| Packaging & Delivery | Standard export package | Different Welding Current AC: | 15 Kinds | ||

| Port: | Shenzhen | ||||

| Max.Welding Current: | 200KVA--4000A | ||||

| Max.Moving Angle Of Crank: | 180 degree | ||||

| Max.Moving Range Of Crank-Arm: | 300mm or can be longer per custsomized products | ||||