IDP5210 precision spot welding machine 4000A

This welding equipment integrates high-definition touch, real-time monitoring, multi-control, fault self-diagnosis, flexible communication, data traceability, safety monitoring, multi-stage discharge and high-frequency adjustment, providing a precise welding experience. It supports multiple parameter settings and storage, adapts to various welding needs, ensures welding quality and stability, and is an efficient and intelligent welding solution.

- SCN CNC

- Guangdong, China

- 7days

- 300 sets/month

- Information

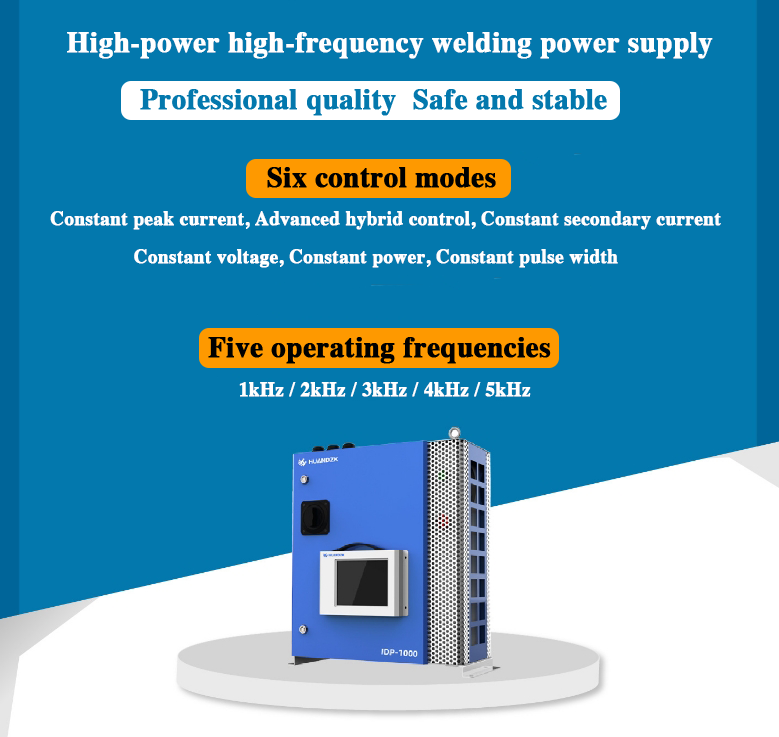

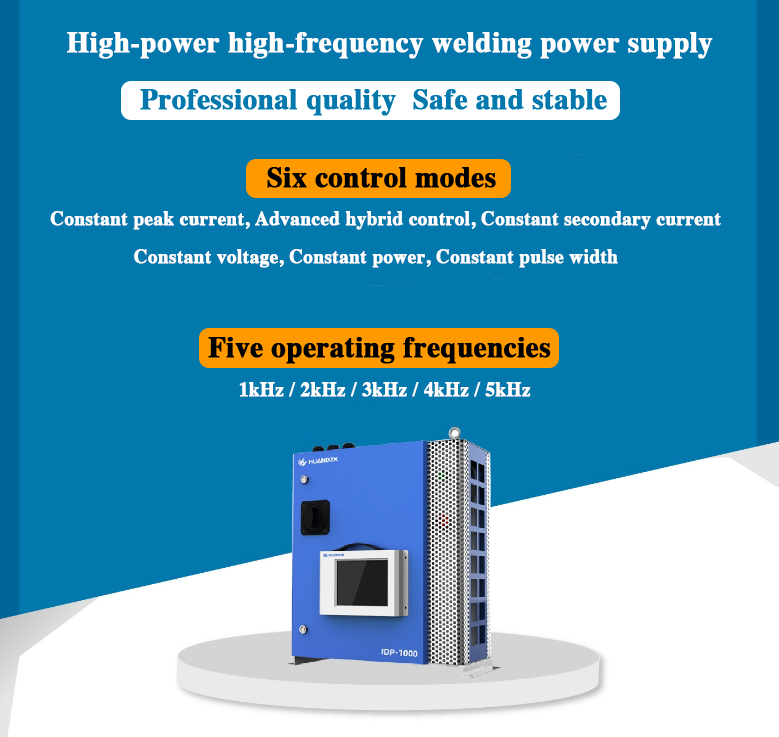

Our spot welder is a cutting-edge spot welding machine designed to meet the highest standards of welding quality control. With the ability to precisely control 1A current and featuring 6-mode control along with a 5-speed operating frequency, this welding power supply ensures optimal performance in various welding applications.

Equipped with an integrated touch interface, operators can easily navigate through settings and adjustments, enhancing user experience and efficiency. The inclusion of oscilloscope monitoring provides real-time feedback on the welding process, ensuring accuracy and consistency in every weld. Additionally, the spot welder is capable of storing up to 5 million solder joint data points, enabling comprehensive quality control and analysis for continuous improvement.

One of the key features of our spot welding transformer is the pressure displacement monitoring system, which plays a crucial role in ensuring welding accuracy. This feature is particularly beneficial for applications that require ultra-precision, such as electronic medical parts. With its advanced technology and precise control capabilities, our spot welder is the ideal solution for industries that demand top-notch welding performance and quality control.

Most of the time, our wire forming machine technical engineers in debugging products, often one step difference, will lead to the equipment produced by the product is not stable, and the accuracy can not meet the requirements. At this time, the adjustment machine master needs to calm down, find the reason and solve the problem. What are the main reasons for the unstable production of the product...more