High-frequency inverter DC welding power supply: the leader of welding technology innovation

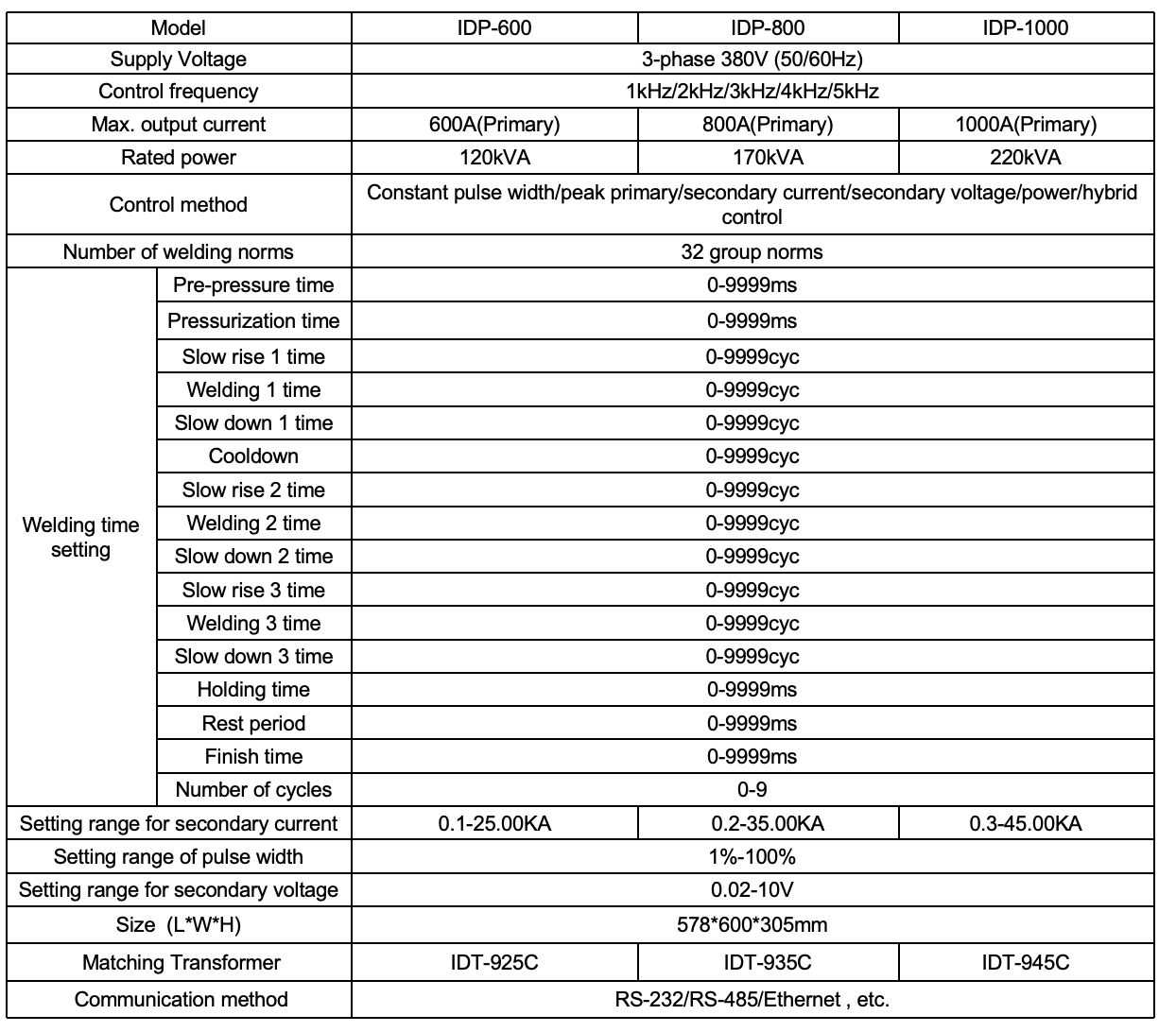

High-precision control of 0.2ms and low heat generation to create beautiful and stable solder joints. It integrates current, voltage, power, pressure, and displacement monitoring, and has pre-detection alarm and powerful quality traceability capabilities (recording more than 5 million data). The welding frequency can be flexibly switched between 1-5KHZ to meet various needs.

- SCN CNC / HUANDZK

- Guangdong, China

- 7days

- 500 sets / month

- Information

In the industrial age of pursuing the ultimate welding effect, we grandly launch the high-frequency inverter DC welding power supply, a welding equipment that combines cutting-edge technology and excellent performance. Ultra precision welding power supply not only redefines the standard of welding technology, but also becomes an indispensable assistant in many industries with its unique product characteristics and wide application scenarios.

Product Features

High-frequency inverter technology:

The most advanced high-frequency inverter technology is adopted to achieve efficient conversion and precise control of energy. This technology not only improves welding efficiency, but also ensures stable and uniform energy output during welding, thereby improving welding quality.

High-precision control:

The control accuracy of 0.2 milliseconds allows each welding to achieve micron-level accuracy. Whether welding power supply is subtle weld adjustment or complex welding path planning, welding power supply can be easily handled to ensure flawless welding results.

Low heat generation design:

By optimizing the internal structure and adopting efficient heat dissipation technology, this precision welding power supply generates extremely low heat during operation, effectively extending the service life of the equipment and reducing energy consumption. This is especially important for long-term, high-intensity welding operations.

Intelligent monitoring and early warning: integrated multi-parameter real-time monitoring functions, including current, voltage, power, pressure and displacement (penetration depth), etc., to provide operators with comprehensive welding status information. At the same time, the pre-detection and alarm reminder functions can timely warn potential problems before they occur, ensuring safe and worry-free production.

Powerful data recording capability:

Built-in high-performance data recording system, which can store more than 5 million welding data. These data can not only be used for the traceability and analysis of welding quality, but also provide strong support for process improvement and efficiency improvement.

Flexible welding frequency:

Supports welding frequency switching from 1KHZ to 5KHZ to meet the welding needs of workpieces of different materials and thicknesses. This feature enables this precision welding power supply to perform well in a variety of application scenarios.

Application scenarios

Automobile manufacturing:

In the field of automobile manufacturing, high-frequency inverter DC welding power supplies are widely used in key links such as body welding and component connection. Its high-precision and high-efficiency welding characteristics ensure the stability and safety of the automobile structure.

Aerospace:

In the field of aerospace, the requirements for welding quality are extremely demanding. High-frequency inverter DC welding power supply has become an ideal choice for manufacturing high-precision and high-reliability aviation parts with its excellent performance and stable quality.

Electronics and electrical appliances:

In the electronics and electrical appliances industry, high-frequency inverter DC welding power supply is used for circuit board welding, precision component connection and other operations. Its low heat generation design and intelligent monitoring function effectively guarantee the quality and stability of electronic products.

Metal products:

In the field of metal product processing, high-frequency inverter DC welding power supply can be used for welding and cutting of various metal materials. Its powerful welding ability and flexible welding frequency make the processing process more efficient and accurate.

High-frequency welding transformer is specially designed for high-frequency welding, with high-efficiency conversion, stable output, rapid response, adapting to various welding needs, helping to improve welding accuracy and efficiency, and widely used in various fields of manufacturing industry.

High-frequency inverter DC welding power supply has become an innovation leader in the field of welding technology with its excellent product characteristics and wide application scenarios. We firmly believe that the emergence of this product will bring higher production efficiency, lower operating costs and better product quality to enterprises. Choosing a high-frequency inverter DC welding power supply means choosing a more efficient, intelligent and reliable welding solution.

Most of the time, our wire forming machine technical engineers in debugging products, often one step difference, will lead to the equipment produced by the product is not stable, and the accuracy can not meet the requirements. At this time, the adjustment machine master needs to calm down, find the reason and solve the problem. What are the main reasons for the unstable production of the product...more