High frequency welding transformer

IDP series precision spot welding machines have the characteristics of high control accuracy (0.2 ms), low heat generation, little damage to the workpiece, good weld appearance, high welding tensile strength, strong welding stability, and low welding defective rate. also supports optional host computer group control and real-time welding quality monitoring system.

- SCN CNC

- Guangdong, China

- 2 days

- 800 sets per month

- Information

We are proud to introduce an advanced system that integrates precision inverter welding power supply, high-frequency welding transformer and all-round comprehensive welding monitor, specially designed for the needs of the automotive industry. The adaptive intelligent welding function, which is standard on the whole series, is like a welding partner with a smart brain, which can keenly capture the changes in the external environment during the welding process, automatically optimize the current and time parameters, and ensure excellent welding quality. Whether resistance spot welding power supply is the problem of shunt, edge welding challenges, non-conductive gap welding bottlenecks, or complex situations such as pressure fluctuations and plate thickness differences, they can be easily dealt with to achieve a perfect upgrade of the welding process.

Remote programming, all in control

Equipped with an advanced remote programmer, you can easily set and adjust welding parameters remotely no matter where you are, greatly improving production flexibility and efficiency.

Multi-frequency selection, precise matching

Five operating frequency options (1KHz to 5KHz) are provided to meet the precise needs of different welding tasks, ensuring that every welding can achieve the best results.

Exquisite touch interface, full of technology

Adopting a high-end human-machine touch interface, high fre is not only exquisitely designed, but also integrates powerful oscilloscope and detector functions. With one-click operation, you can intuitively display the real-time waveforms and detailed data of eight key parameters such as current, voltage, power, and resistance, so that you can fully grasp the welding status.

Intelligent pressure displacement management, safe and efficient

The built-in intelligent pressure displacement management system, including pressure monitoring, trigger mechanism, displacement monitoring and penetration interruption function, comprehensively guarantees the safety and stability of the welding process and improves welding efficiency and quality.

Massive data storage, worry-free traceability

The powerful built-in database can store up to 5 million detailed data of welding points, including key indicators such as current, voltage, power, resistance, pressure, displacement, etc. precision inverter welding power supply supports convenient export of USB flash drives, providing solid data support for welding quality traceability and process optimization.

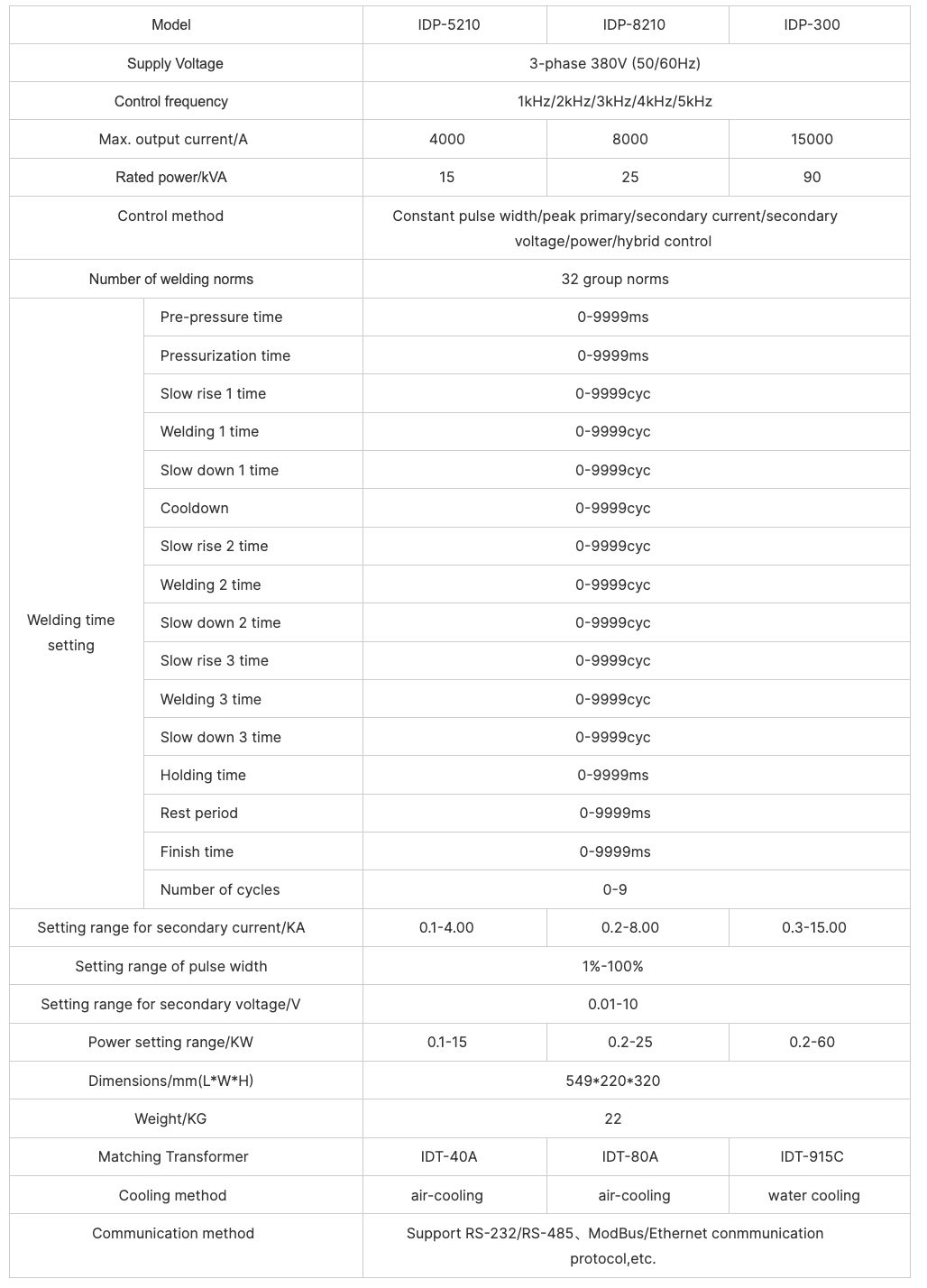

Main Product Parameter

Most of the time, our wire forming machine technical engineers in debugging products, often one step difference, will lead to the equipment produced by the product is not stable, and the accuracy can not meet the requirements. At this time, the adjustment machine master needs to calm down, find the reason and solve the problem. What are the main reasons for the unstable production of the product...more