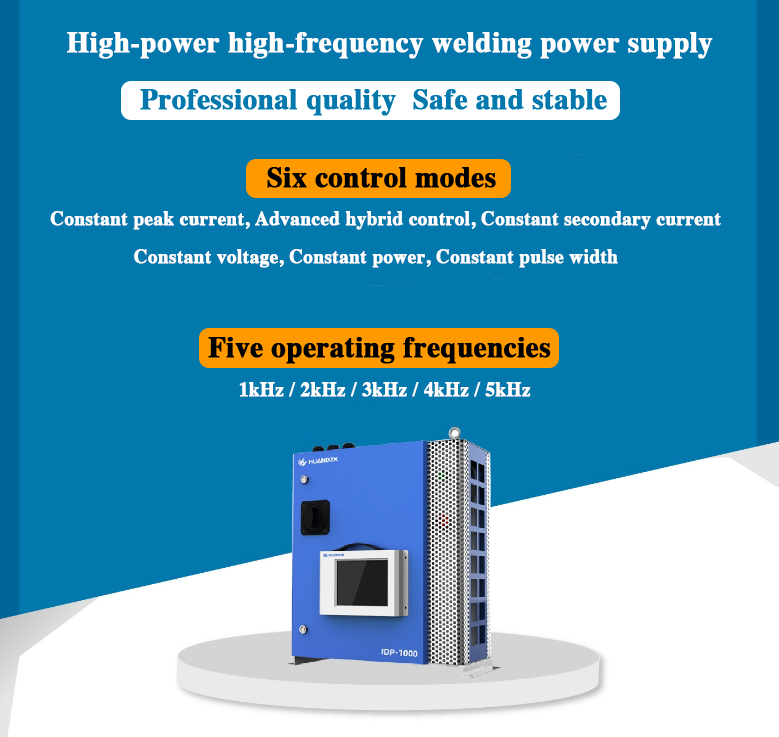

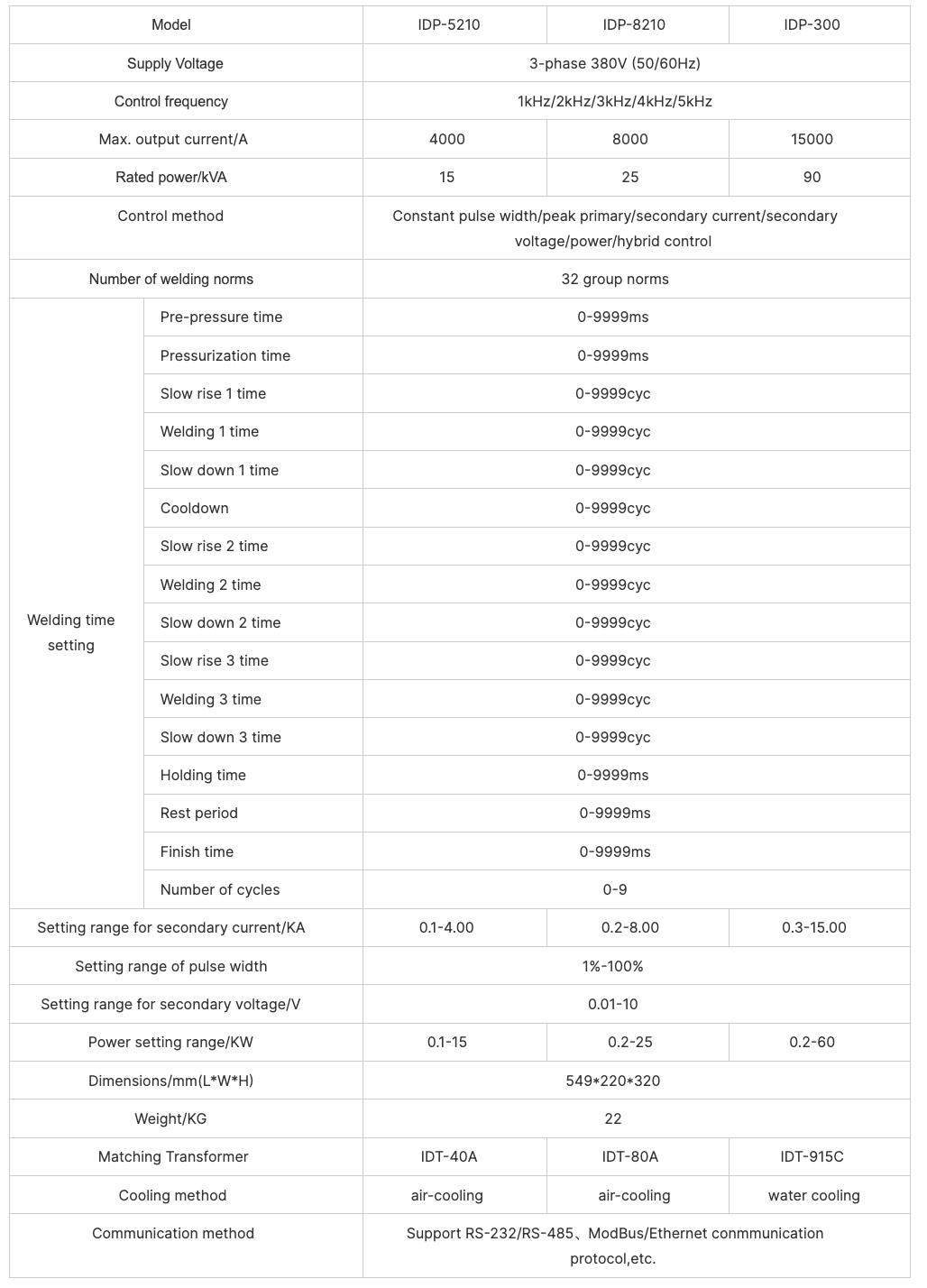

High Power High Frequency DC Welding Power Supply

Resistance welding power supply has the characteristics of high control accuracy (0.2 ms), low heat generation, small damage to the workpiece, good solder joint appearance, high welding tensile strength, strong welding stability, and low welding defective rate.

- SCN CNC / HUANZDK

- Guangdong, China

- 3 days

- 500sets / month

- Information

Introducing our state-of-the-art inverter DC resistance welding power supply, a cutting-edge solution designed to meet the highest standards in welding technology. This advanced power supply unit is engineered to deliver precision, efficiency, and reliability, making resistance welding power supply an ideal choice for a wide range of welding applications.

#### Key Features and Benefits

1. **High control accuracy (0.2 ms):**

One of the standout features of our inverter DC welding power supply is its exceptional control accuracy. With a control response time as fast as 0.2 milliseconds, this power supply ensures precise and consistent welding results. This high level of control minimizes variations, providing a stable welding process that is critical for producing high-quality welds.

2. **Low Heat Generation:**

The advanced design of the inverter technology significantly reduces heat generation during the welding process. This feature not only protects the workpiece from thermal damage but also prolongs the lifespan of the welding equipment. By minimizing heat, our power supply ensures a safer and more efficient welding environment.

3. **Minimal Workpiece Damage:**

The low heat output and precise control of the inverter DC welding power supply result in minimal damage to the workpiece. This is particularly important for delicate or thin materials where excessive heat can cause warping or distortion. Our power supply ensures that the integrity and quality of the workpiece are maintained throughout the welding process.

4. **Excellent Solder Joint Appearance:**

With precision welding power supply's precise control and stable welding parameters, our power supply produces aesthetically pleasing solder joints. The smooth and clean appearance of the welds is crucial for applications where visual quality is as important as structural integrity.

5. **High Welding Tensile Strength:**

The inverter DC welding power supply is engineered to deliver welds with high tensile strength. This strength ensures that the joints are robust and durable, capable of withstanding significant mechanical stresses. Precision welding power supply is particularly beneficial for applications requiring strong and reliable joints.

6. **Strong Welding Stability:**

Stability is a critical factor in welding, and our power supply excels in this aspect. The advanced inverter technology ensures consistent power output, minimizing fluctuations and ensuring a stable welding arc. This stability translates into reliable performance and fewer defects in the final product.

7. **Low Welding Defective Rate:**

Our inverter DC welding power supply boasts a low defective rate, thanks to resistance welding power supply precise control and stable operation. This feature is essential for industries where quality and consistency are paramount, reducing the need for rework and increasing overall productivity.

#### Ideal Applications

The inverter DC resistance welding power supply is suitable for a wide range of applications, including automotive manufacturing, electronics, aerospace, and more. precision welding power supply's versatility and reliability make resistance welding power supply a valuable addition to any production line, ensuring high-quality welds and efficient operation.

Our high frequency welding transformer is a key component in modern welding systems, designed to offer exceptional performance and efficiency. This advanced transformer is engineered to operate at higher frequencies than traditional models, providing numerous advantages in various welding applications.

The resistance welding monitor can detect various types of resistance welding machines and help improve welding quality.Resistance welding monitor can monitor and determine key values such as welding current, voltage, power, welding time, pressure, displacement, etc. and save about 5 million key welding data to prevent unstable welding and cause defective products to flow into the next process.

In summary, our high frequency welding transformer and inverter DC welding power supply offers a perfect blend of precision, efficiency, and reliability. With welding power supply advanced features and robust performance, precision welding power supply stands out as an excellent choice for all your resistance welding needs.

Most of the time, our wire forming machine technical engineers in debugging products, often one step difference, will lead to the equipment produced by the product is not stable, and the accuracy can not meet the requirements. At this time, the adjustment machine master needs to calm down, find the reason and solve the problem. What are the main reasons for the unstable production of the product...more