Precision inverter welding power supply

The first servo motor control to achieve precise and adjustable welding pressure; diversified control modes and adjustable working frequency to meet the needs of multiple scenarios; exquisite human-machine interface with integrated oscilloscope function to intuitively display welding data; large-capacity data storage and support for export to facilitate data analysis; real-time quality monitoring to ensure excellent welding quality.

- SCN CNC

- Guangdong,China

- 2 days

- 1000sets / month

- Information

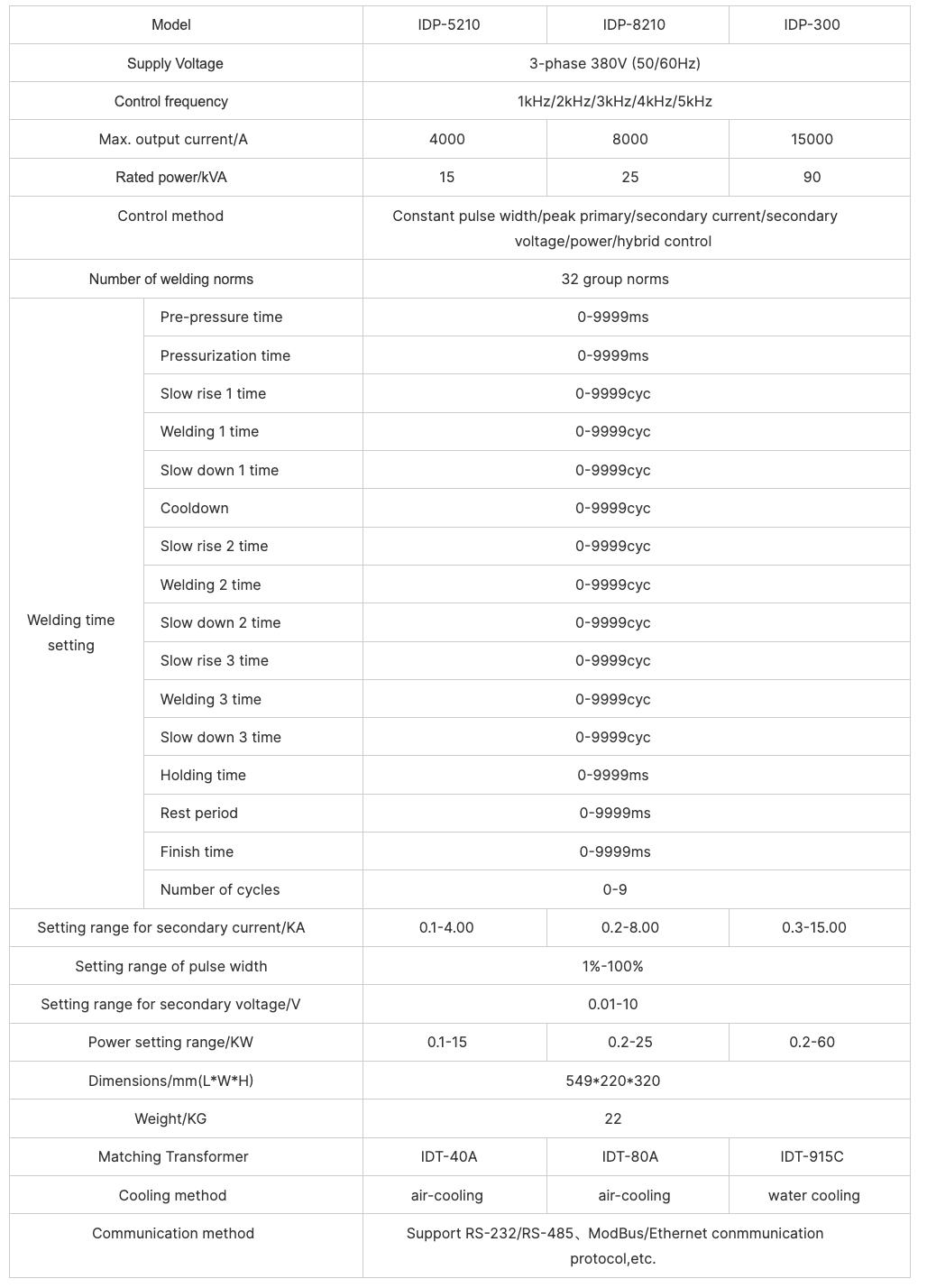

This precision inverter welding power supply, as the most popular model with the most abundant configuration on the market, leads the industry trend with its excellent performance and innovative technology. It provides 6 flexible control modes and 5 optional working frequencies from 1KHz to 5KHz to meet the delicate needs of different welding processes and materials.

It is particularly worth mentioning that the welding machine power supply is equipped with the industry's first servo motor control function. This revolutionary design realizes the precise adjustment of multiple pressures during welding. At the same time, the welding head reset distance can also be freely set, which effectively solves the problem caused by the instantaneous impact of the welding head under the traditional cylinder method, and significantly improves the stability of welding and the quality of finished products.

Its exquisite human-machine touch interface integrates oscilloscope and detector functions, and can display 8 real waveforms such as current, voltage, power, resistance and corresponding welding data in real time, making the operation more intuitive and convenient, and the monitoring more comprehensive and detailed. In addition, the precision resistance welding power supply for spot welding also supports pressure displacement control, built-in pressure monitoring, pressure triggering, displacement monitoring and displacement penetration interruption functions, ensuring that every detail of the welding process is under control.

To meet the data management needs of large-scale production, the welding machine power supply also has a powerful built-in database function, which can store detailed data of about 5 million welding points, including key parameters such as current, voltage, power, resistance, pressure, displacement, etc., and supports easy export through a USB flash drive, which is convenient for subsequent data analysis and quality traceability.

Finally, the precision resistance welding power supply also has the ability to monitor the average effective value and instantaneous value of current, voltage, and power in real time, helping users to accurately control the welding quality and ensure that each welding can achieve the best effect. Whether in terms of technological innovation, ease of operation or data management capabilities, this spot welding power supply is a rare high-performance product on the market.

Main Product Parameter

Most of the time, our wire forming machine technical engineers in debugging products, often one step difference, will lead to the equipment produced by the product is not stable, and the accuracy can not meet the requirements. At this time, the adjustment machine master needs to calm down, find the reason and solve the problem. What are the main reasons for the unstable production of the product...more