Resistance Spot Welding Inverter Cold Welding Machine Stainless Aluminum Power

It supports free switching of frequencies from 1khz to 5Khz, and the maximum control cycle is 0.2ms. Compared with conventional AC machines, the control frequency is increased by 100 times. Compared with similar products, the control response and accuracy are high, and the inverter technology is more advanced!

- SCN CNC

- Guangdong,China

- 3days

- 800sets / month

- Information

The high-frequency precision welding power supply is a groundbreaking solution designed to elevate the standards of welding technology. With precision welding power supply innovative inverter technology, this power supply supports frequency switching from 1kHz to 5kHz, offering a control cycle as fast as 0.2ms. This represents a 100-fold increase in control frequency compared to conventional AC machines and surpasses competitors in terms of control responsiveness and accuracy.

One of the key features of this welding power supply is its versatility, offering six distinct control modes: secondary constant current, primary constant current, constant voltage, constant power, constant pulse width, and advanced hybrid control. These modes ensure adaptability across a wide range of complex welding scenarios.

The 8-inch high-definition touch screen provides a clear and intuitive user interface, integrating oscilloscope and detector functions. Real-time display of up to eight true welding waveforms, including current, voltage, power, and resistance, enables precise monitoring of welding consistency and quality.

An industry-first servo force control function is included, allowing for precise adjustment of welding pressure in multiple stages and customizable retraction distance. This feature mitigates the impact issues commonly associated with pneumatic cylinder welding heads, particularly crucial in projection welding processes.

For stringent quality control, the machine supports pressure triggering, ensuring consistent pressure during each weld. Additionally, the precision welding power supply offers displacement depth control, stopping the power supply once the specified displacement is reached, guaranteeing uniform melt depth in the welded product.

The built-in database can store approximately 5 million records of welding data, including current, voltage, and power values. This data can be exported via USB for detailed analysis and quality traceability. The system also includes a historical alarm record module to assist in troubleshooting.

With automatic welding monitor, the system can detect deviations in current, voltage, power, pressure, and displacement, alerting operators to potential issues. Welding monitor incorporates over 22 diagnostic and protective measures, enhancing both safety and weld quality.

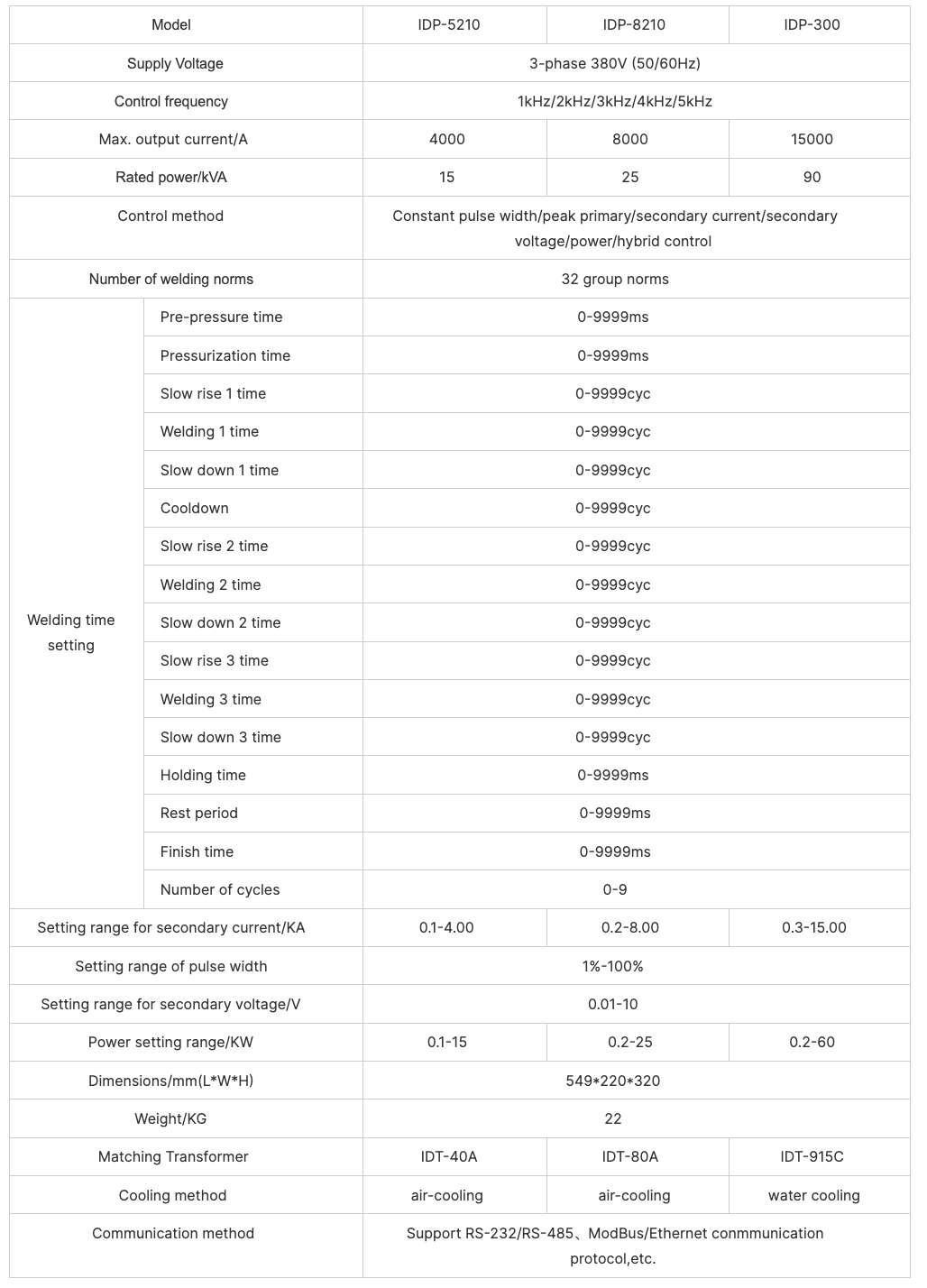

The power supply offers extensive connectivity options, including 32 parameter storage slots, multiple I/O interfaces, and support for various communication protocols such as MODBUS, RS-232, RS-485, and Ethernet, facilitating seamless integration into automated systems.

Finally, the integrated counter and permission management system ensures accurate tracking of welding operations and secure access levels for different users. This comprehensive suite of features makes the high-frequency precision welding power supply an indispensable tool for achieving exceptional welding results.

Most of the time, our wire forming machine technical engineers in debugging products, often one step difference, will lead to the equipment produced by the product is not stable, and the accuracy can not meet the requirements. At this time, the adjustment machine master needs to calm down, find the reason and solve the problem. What are the main reasons for the unstable production of the product...more