News

At the Canton Fair 2025, China’s leading welding power supply manufacturer will exhibit advanced Pulse Hot Press Welding systems, Resistance Spot Welders, and Welding Monitoring Instruments. With self-developed control and precision technology, the company brings smart, efficient welding solutions for global electronics, automotive, and new energy industries.

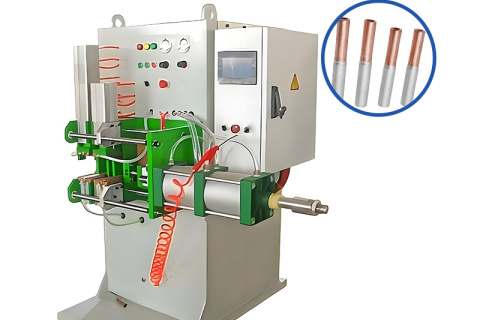

Our energy storage welding power supply delivers fast, stable, and consistent welding performance. Featuring capacitor discharge technology, it ensures high peak current, short welding time, and precise control. Ideal for battery tabs, connectors, and precision metal parts, it boosts efficiency while maintaining excellent quality and safety for modern automated production lines.

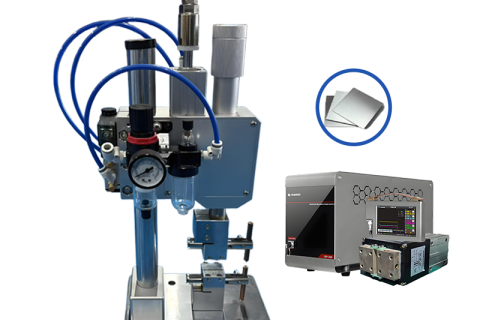

We specialize in pulse hot press welding, thermocompression welding machines, and hot bar welders with intelligent welding monitoring devices. Our systems ensure precise, reliable, and repeatable nickel strip welding for electronics, batteries, and precision assemblies, providing real-time quality monitoring, data traceability, and superior bonding performance. Trusted globally for efficiency and consistency.

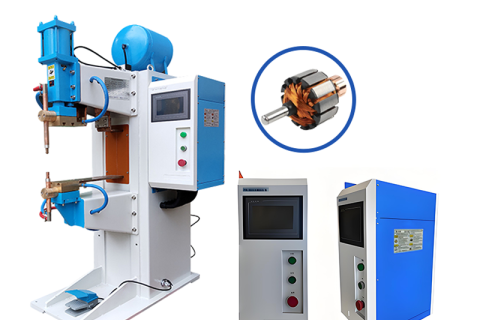

As a top resistance welding power supply manufacturer in China, we will showcase our latest precision welding power supplies, hot bar welding power supplies, and welding analyzer equipments at the 2025 Canton Fair. With advanced control technology, stable performance, and intelligent monitoring, our solutions redefine reliability and precision in micro joining and electronic assembly.

At the 2025 Canton Fair (Oct 15–19, Guangzhou), China’s largest resistance welding power supply manufacturer presents its latest IDP series welding power supplies, welding monitors, pulse heat welding, and capacitor discharge welding systems—showcasing precision control, intelligent monitoring, and advanced welding technology for global industries including electronics, automotive, and energy applications.

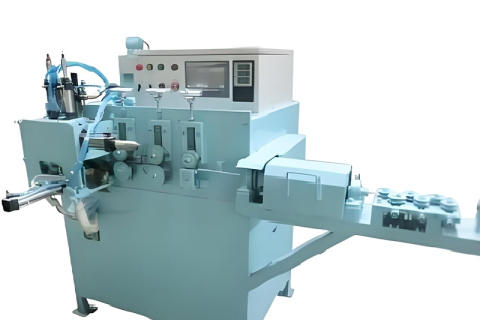

Explore the latest pedal pair welding machines and welding transformer manufacturers at the Canton Fair, featuring high-efficiency welding equipment for resistance welding that delivers precision, durability, and intelligent control for modern industrial applications.

At Canton Fair (Oct 15-19), discover Chinese-made resistance welding power supplies, welding monitors, precision spot welders, transformers, and controllers. These offer Miyachi/Bosch-level quality at localized prices, ideal for cost-effective, high-performance manufacturing. Visit us for advanced solutions.

Professional welding power supply manufacturer providing hot bar soldering machine, resistance spot welding machines, and precision resistance welding solutions worldwide.

Our welding solutions include the resistance roll welding machine, resistance bumper welding machine, and industrial pneumatic spot welding machine, powered by advanced welding machine power supply systems. These machines ensure precision, strength, and efficiency, serving automotive, electronics, and industrial sectors with reliable weld quality, productivity, and long-term performance.

Comprehensive resistance weld monitoring systems. Reliable resistance welding power supply technology. Durable butt resistance welding machine designs. Competitive china made spot welding machine solutions.