News

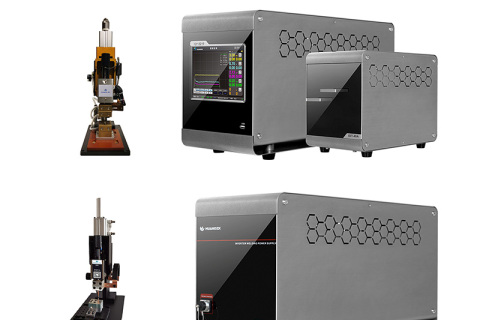

The HD-400B welding monitoring device has the following notable advantages: high-precision real-time monitoring, comprehensive data analysis, wide applicability, excellent standard discrimination, large-screen viewing display, enhanced data traceability, rich communication interfaces and efficient statistical monitoring.

IDP series precision welding power source is independently developed by Huandian, using imported components and advanced technology. It has the functions of welding quality control, data monitoring and traceability, high control accuracy, low heat generation, excellent solder joints, strong tension, good stability, low defect rate, and also supports networking group control and quality monitoring.

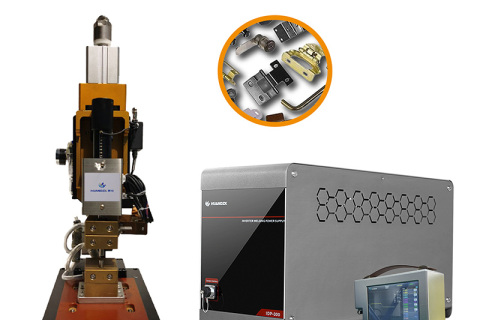

Precision inverter resistance welding provides solutions for metal contact welding, with many advantages, such as high efficiency and good solder joints. Precision inverter resistance welding power supply features include DC output, intelligent control, soft switching technology, etc. DC inverter resistance spot welding machine has fast response and high precision, and is very suitable for precision welding, with broad application prospects.

Precision spot welding machine is a high-precision welding equipment, combined with digital pulse control inverter technology, widely used in mold, hardware, casting, machinery and other industries. Inverter spot welding machine advantages are that the welding parameters can be accurately adjusted, the heat is small, and the welding strength is high, so the market prospect is broad. This article will analyze in detail the working principle, application field and future market development trend of precision spot welding machine.

Huandian inverter precision welding controller has six control modes to accurately adapt to the needs, multiple working frequencies for flexible selection, servo motor voltage control and stable, clever combination of pulse discharge, excellent human-machine interface, complete monitoring functions, and convenient data storage, which can provide efficient and stable resistance welding throughout the process.

Weld penetration is a key indicator to measure the quality of resistance welding and is significantly affected by factors such as current and pressure. Advanced testing equipment can monitor welding parameters in real time, accurately determine quality and trace data, comprehensively improving welding strength, sealing and service life.

Weld penetration testing methods include metallographic microscope observation, compression test and weld penetration microscope observation. Weld penetration tester measures the temperature change during welding through thermocouples, and the computer analyzes the data to determine the penetration depth. Resistance welding penetration tester helps to optimize welding parameters, monitor the welding process in real time, and ensure welding quality.

The resistance welding process achieves metal workpiece welding through high-precision current control. Hand operated spot welding machine is suitable for metal products with a diameter of 0.1mm~9mm. Hand held spot welding machine is adopted in automated production lines and has the advantages of flexibility, high efficiency and no need for consumables.

As a core component, the Huandian spot welding machine controller realizes efficient and precise welding, innovates frequency switching and servo motor control, and has complete and leading functions. It is the result of long-term research and development and technological iteration, and can meet high-demand welding needs.

Huandian specializes in the manufacture of high-precision spot welding machines, providing a variety of excellent performance equipment with ultra-high welding accuracy and powerful quality monitoring systems. Through continuous research and development and innovation, Huandian leads the industry in welding control accuracy, functional stability and production efficiency to meet the diverse needs of customers.