News

Due to their different frequency characteristics, medium-frequency DC inverter transformers and high-frequency DC inverter transformers are suitable for industrial heating, medical equipment, new energy, and communications fields, respectively78. This article analyzes the advantages and disadvantages of the two in terms of efficiency, anti-interference, load adaptability, and cost, and provides a technical basis for selection.

Medium frequency DC transformers are efficient, compact, low harmonic, and suitable for new energy, industry, and transportation. They empower the future of green energy with high-frequency devices and innovative control.

China's top welding power supply and spot welding machine manufacturer appeared at the Kielce Spring Industrial Exhibition in Poland, demonstrating its core technologies and intelligent solutions, which won praise from customers. On-site practical operations promoted transactions and exhibition expectations were achieved.

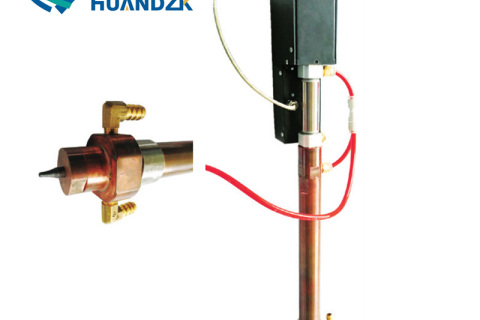

Resistance welding transformers have high welding efficiency, fast speed, strong weldment, and reduce welding costs. They are suitable for welding a variety of materials, such as aluminum alloys and aluminum and other materials with fast thermal conductivity and poor weldability. In addition, for the welding of galvanized sheets and ordinary multi-layer sheets, welding transformer's welding quality is also much higher than that of power frequency welding machines.

At booth 1A-A16 at the Polish Spring Industrial Exhibition, welding power supply manufacturers will showcase their cutting-edge welding technology matrix, with independent research and development, international quality, and intelligent monitoring to help reduce costs and increase efficiency.

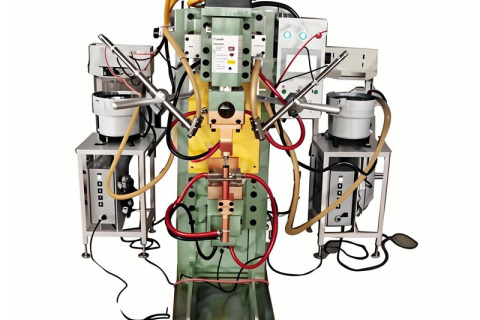

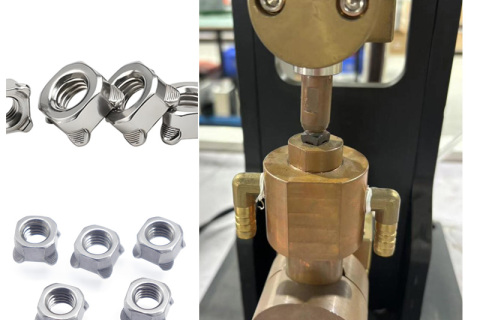

Automatic feeding nut spot welding machine, with high efficiency and precision welding, environmental protection and energy saving, is widely used in the fields of automobile, aerospace, electronics and rail transportation, helping to upgrade industrial manufacturing.

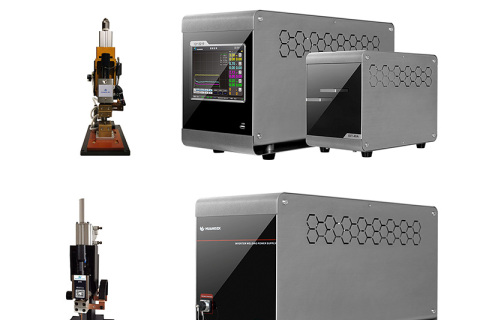

Huandian DC inverter welding power supply is efficient and stable, with high welding quality, convenient intelligent management, and guaranteed safety. Dc inverter welding power supply is suitable for high-quality welding needs, but the cost is relatively high.

The precision spot welding machine adopts 0.2 ms high-precision control 6 and servo pressure system, combined with mechanical positioning and electrical signal detection dual anti-reverse technology, to achieve low thermal damage and high stability in nut welding. The strength of the weld point reaches more than 90% of the parent material, and the defective rate is less than 0.5%. It is widely used in high-precision manufacturing fields such as automobiles and electronics.

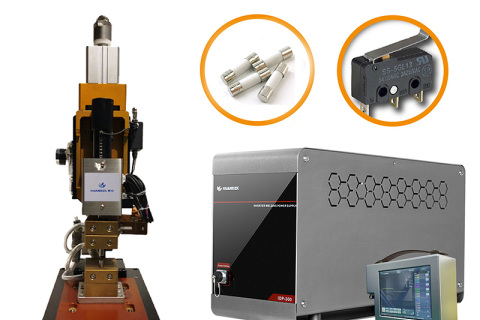

The nut error prevention monitoring system integrates error prevention, counting and management. It uses high-precision sensors and MCU to ensure that the nut welding is correct, improve production efficiency and quality, and meet diversified production needs.

The projection welding nut error-proofing detector improves welding quality and efficiency, prevents errors, and helps efficient production. Projection welding nut error-proofing detector is a powerful assistant and high-quality equipment in industrial production.