News

As a leading welding power supply company in Huizhou, we serve global automakers and battery manufacturers with cutting-edge technologies such as high-frequency inverters. We also offer free trial welding and invite you to collaborate during the September purchasing season!

HWD’s HT-300 and HT-500 pulse heating welders deliver fast, precise, and stable welding for FPC/PCB, semiconductor chips, LED, sensors, and battery tabs. Ideal for electronics, automotive, renewable energy, and medical device industries, these welders combine advanced temperature control, real-time monitoring, and high efficiency for reliable high-precision production.

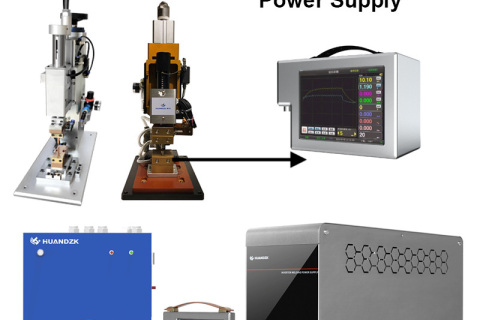

The pulse hot pressure welding power supply created by the resistance welding manufacturer has precise temperature control and strong adaptability of the welding head. It is suitable for electronics, automobiles, new energy and other fields, providing stable and efficient welding solutions and perfect after-sales service.

Urwelder and university doctors jointly developed the H-300 and H-500 pulse heating power supplies, integrating five-stage heating, full-process visualization, intelligent monitoring and MES interconnection to fully support high-end precision manufacturing.

At Canton Fair 2025, discover Chinese-made resistance welding power supplies, welding monitors, precision spot welders, transformers, and controllers. These solutions rival Miyachi and Bosch in quality—featuring closed-loop control and real-time monitoring—but at competitive local prices. Ideal for global manufacturers seeking advanced, cost-effective welding technology. Visit from Oct 15-19 in Guangzhou.

The IDP-Pulse pulse heating welding machine features precise multi-stage pulse temperature control, ultra-thin welding without heat loss, intelligent closed-loop monitoring, and compatibility with automated production lines, efficiently enabling precision manufacturing!

This spot welder is equipped with a high-precision IDP-8210 precision resistance welding power supply, which has the function of accurately judging welding quality. It supports multi-stage discharge and slow rise and fall, effectively avoiding current shock and ensuring stable and consistent welding. It supports host computer group control to achieve centralized management of multiple machines.

Capacitor energy storage spot welders have rapid discharge and minimal thermal impact, making them suitable for high-precision welding applications. Compatible with medium-frequency resistance welders, welding inverters, and welding analyzers, they are an ideal upgrade solution for high-frequency spot welders.

The IDP-1210 ultra-precision resistance welding power supply features 0.1ms control accuracy, supports multi-stage welding control and quality judgment, and offers stable, accurate and reliable welding, intelligent judgment, and multi-interface communication, making it suitable for demanding precision welding scenarios.

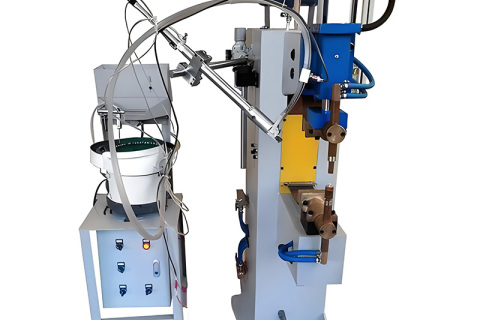

The nut automatic feeding welding machine combined with the IDW-200 anti-reverse detector realizes efficient, accurate and intelligent nut welding. It is widely used in industries such as automobiles, home appliances, and electronic equipment, significantly improving production efficiency and product quality.