- Home

- >

News

380V copper wire welding machine is known for its high efficiency and reliability, and is widely used in the fields of electronics and electrical appliances. Its high-precision welding technology ensures quality and is suitable for copper wires of multiple specifications. When choosing, you need to consider power, technical parameters and brand quality. Huandian IDP series inverter DC welding power supply uses imported components and advanced technology to provide precise control and low-damage welding, helping enterprises to produce efficiently.

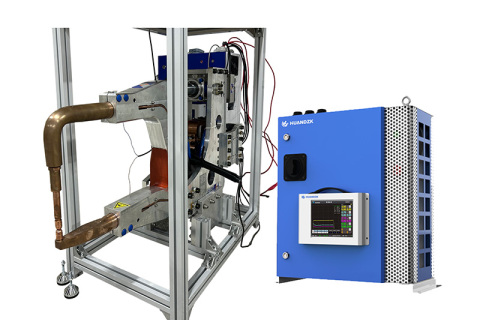

Ur welder provide high power high frequency DC welding power supplies, resistance spot welders, resistance weld monitorings, and professional customized automotive suspension spot welding solutions to ensure efficient and stable welding.

Precision resistance welding machines are widely used in the electronics, battery, automotive and medical industries. With high-precision welding power supplies, welding transformers and welding monitors, they can achieve efficient and stable welding and help upgrade smart manufacturing.

During the Spring Festival holiday from January 20 to February 5, 2025, we suspended production but the business team was on standby. The core products include welding power supplies and intelligent solutions, with innovative functions such as multi-stage welding and servo control.

We provide advanced welding solutions, including precision power supplies, spot welding power controller, spot welding machine transformer, and welding quality inspection device. Our products enhance welding quality, control, and efficiency, offering real-time monitoring, data analysis, and network integration for improved performance and traceability.

The selection of electrode material and shape for precision spot welding machines is crucial, affecting welding quality, cost and efficiency. Materials such as chromium zirconium copper, beryllium copper, aluminum oxide copper, tungsten and molybdenum each have their own advantages and need to be selected as needed.

High-efficiency welding capability, high precision and stability, wide applicability, intelligent operation, energy saving and environmental protection

High-efficiency welding capability, high precision and stability, wide applicability, intelligent operation, energy saving and environmental protection

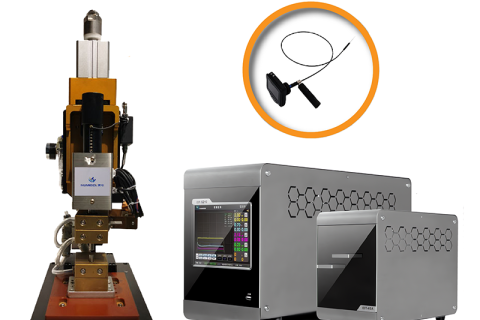

Ultra Precision Welding Power Supply, Precision Inverter Welding Power Supply, High Power High Frequency DC Welding Power Supply, High Frequency Welding Transformer, Welding Monitor

The inverter welding power supply integrates high efficiency and intelligence. Through intuitive touch screen, real-time waveform monitoring, pressure displacement control and powerful database, it realizes precise control and data analysis of the welding process, significantly improving welding quality and efficiency.

This welding equipment has a high-precision control of 0.2ms and low heat generation to create beautiful and stable solder joints. It integrates current, voltage, power, pressure, and displacement monitoring, and has pre-detection alarm and powerful quality traceability capabilities (recording more than 5 million data). The welding frequency can be flexibly switched between 1-5KHZ to meet various needs.